In the realm of large-scale vaccine distribution, sheer volume is insufficient without uncompromising temperature precision. As global immunization initiatives expand to confront seasonal influenza, emergent COVID-19 variants, and localized disease outbreaks, public health agencies must balance two critical imperatives: operational scale and thermal integrity. Even a brief lapse in cold chain conditions can compromise thousands of doses, jeopardizing not only clinical efficacy but also public trust and program continuity.

To address these high-stakes challenges, Nordic Cold Chain Solutions delivers a purpose-built system that merges capacity with control: the 1800 CRT Pallet Shipper in concert with its specialized Gel Pack Conditioning Program. This dual solution is engineered to meet the stringent thermal compliance standards set forth by the WHO, CDC, and global regulatory bodies. It offers a harmonized approach that ensures bulk vaccine shipments are not only scalable and repeatable, but also thermally secure from origin to endpoint, providing both logistical confidence and regulatory assurance.

The Scale and Sensitivity of Vaccine Pallet Shipping

Vaccines rank among the most thermally sensitive biological products in the pharmaceutical supply chain. Even slight deviations from the critical 2°C to 8°C range, or prolonged exposure to unregulated temperatures, can compromise their potency or result in complete product degradation. Within large-scale distribution efforts, these risks are further magnified by high shipment volumes, geographic dispersion, and the inherent complexity of global logistics.

The 1800 CRT Pallet Shipper was engineered to address this challenge directly.

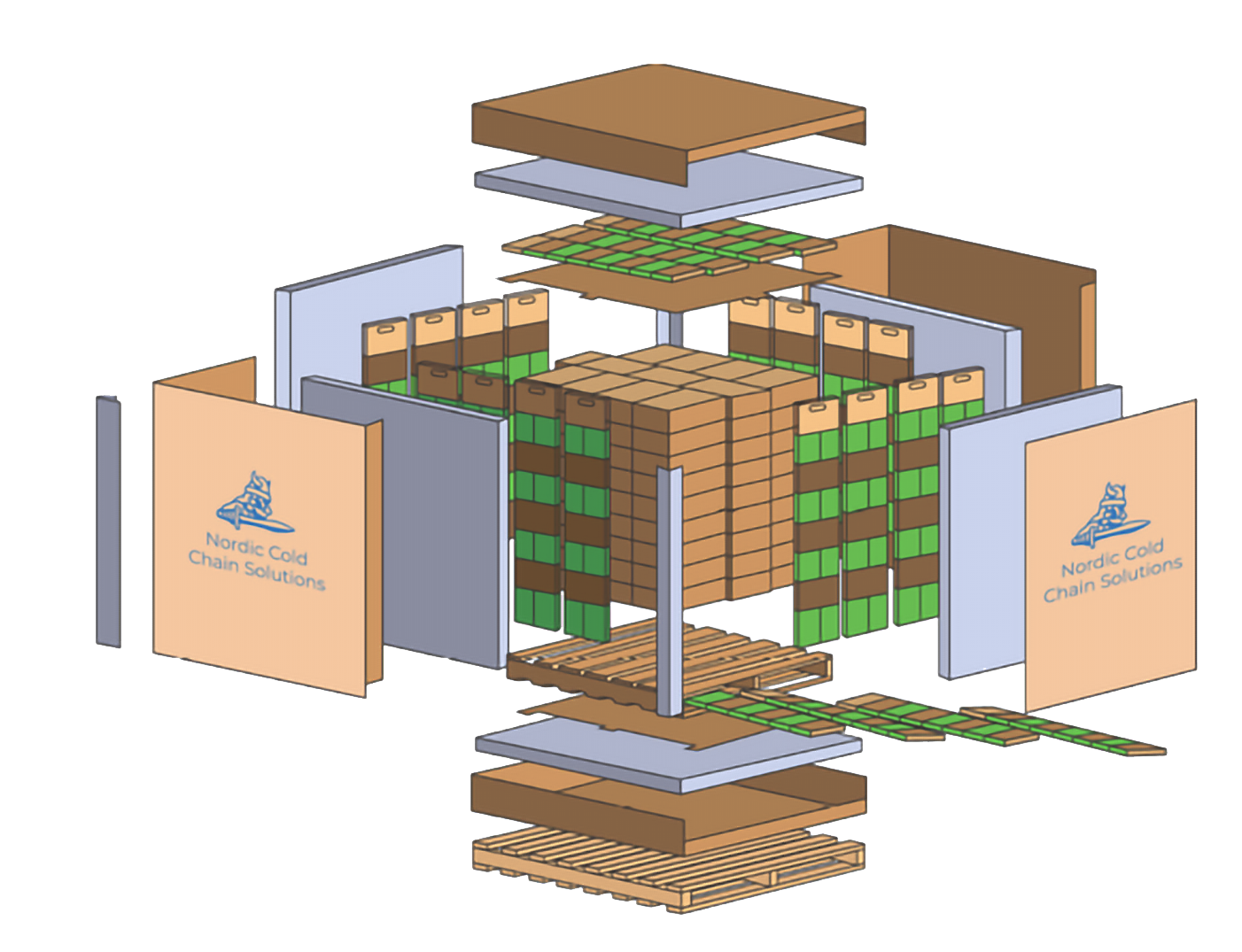

Designed for bulk pharmaceutical transport, it offers:

- Optimized Payload Efficiency: Full U.S. pallet capacity with external dimensions of 57-5/8″ L x 46-5/8″ W x 58-1/8” H accommodates high-volume vaccine shipments without compromising structural integrity.

- Air Freight Compatibility: Four units fit securely on a PMC/LD7 air cargo pallet, enabling seamless integration with global air freight networks.

- Thermal Longevity: Maintains CRT temperature conditions for five or more days, validated against real-world scenarios such as summer tarmac delays and customs holds.

- Flat-Pack Shipping: Units ship unassembled for inbound cost efficiency and are quick to assemble onsite at distribution centers or contract pack-out facilities.

This makes the 1800 CRT ideal for both emergency stockpiles and coordinated global immunization campaigns, providing pharmaceutical companies, NGOs, and government agencies with a scalable container that protects payload integrity over long-haul and last-mile phases alike.

Gel Conditioning: The Invisible Engine Behind Thermal Compliance

Even the most advanced pallet shipper is only as effective as the thermal core that drives its performance, which is why Nordic’s Gel Pack Conditioning Program is a critical component of reliable cold chain execution. Conditioned gel packs function as the active refrigerant within the system, precisely calibrated to absorb and release thermal energy in response to external temperature fluctuations. When improperly conditioned due to uneven freezing, inaccurate target temperatures, or mistimed preparation, they can create internal hot spots, shorten protective duration, and expose shipments to regulatory non-compliance. Nordic’s program eliminates these risks through meticulous, science-backed protocols that ensure consistent, validated thermal performance throughout the entire journey.

Nordic’s program eliminates these risks through:

Customized Conditioning Protocols

Each gel pack is prepared according to a shipment’s exact requirements, factoring in:

- Transit duration and routing

- Seasonal ambient conditions

- Vaccine type and stability range

- Packaging configuration

This level of specificity ensures that every shipment is protected by a refrigerant profile designed not for theoretical lab conditions, but for real-world logistics.

Rigorous Quality Assurance

From thermal mapping and freeze point validation to visual inspection and cycle documentation, every gel pack undergoes multi-point quality checks before it is approved for deployment. This helps ensure:

From thermal mapping and freeze point validation to visual inspection and cycle documentation, every gel pack undergoes multi-point quality checks before it is approved for deployment. This helps ensure:

- Uniform phase change behavior

- Temperature stability over multi-day transit

- Leak resistance and durability under compression

Seamless Operational Integration

Nordic’s gel packs are delivered fully conditioned, labeled, and ready for immediate use, reducing pack-out time and minimizing the risk of human error during staging. Whether incorporated into centralized warehouses or regional distribution nodes, the program supports:

- High-speed staging operations

- Manual or automated kitting workflows

- On-demand replenishment for dynamic distribution models

A Unified System for CRT Vaccine Assurance

The true power of Nordic Cold Chain Solutions lies in the seamless integration of its two core components: the 1800 CRT Pallet Shipper and the Gel Pack Conditioning Program. Rather than functioning as isolated tools, these elements are engineered to work in concert as a cohesive thermal shipping ecosystem. This synergy enables vaccine distributors to maintain uncompromising temperature control across complex global supply chains, while optimizing operational efficiency at scale.

By leveraging both, vaccine distributors can achieve:

Validated Thermal Stability

Together, the pallet shipper and gel packs provide temperature consistency through extended supply chains, including variable ambient conditions, customs clearance delays, and regional delivery routes.

Regulatory Compliance

Solutions are designed in accordance with WHO PQS, CDC VFC, and GDP standards. Full chain-of-custody documentation and thermal performance records support audit-readiness for public and private stakeholders alike.

Scalability and Repeatability

With standardized pack-out procedures and predictable performance curves, Nordic enables distributors to scale operations across multiple sites and geographies without sacrificing quality.

Reduced Waste and Risk

Minimizing temperature excursions directly reduces product loss, supports higher immunization throughput, and lessens the environmental burden associated with repackaging or dose disposal.

Minimizing temperature excursions directly reduces product loss, supports higher immunization throughput, and lessens the environmental burden associated with repackaging or dose disposal.

In a distribution landscape where both precision and agility are non-negotiable, Nordic Cold Chain Solutions offers more than just packaging; it delivers a strategic advantage. By uniting advanced palletized shipping with rigorously conditioned gel refrigerants, Nordic empowers healthcare providers, NGOs, and pharmaceutical companies to meet global vaccine demands with confidence, consistency, and compliance. This unified system does not merely support vaccine campaigns; it strengthens their reliability, enhances their reach, and safeguards the integrity of every dose delivered.

Built for the Future of Vaccine Logistics

As vaccination programs continue to evolve, whether responding to new pathogens, expanding to underserved populations, or adapting to mRNA platforms, the infrastructure behind cold chain logistics must be both resilient and adaptable. Nordic Cold Chain Solutions is at the forefront of this transformation, combining product innovation with cold chain expertise to help public health programs deliver safely, efficiently, and at scale.

The stakes are too high for thermal variability, and the margins for error are too narrow to rely on disjointed systems. With the 1800 CRT Pallet Shipper and Nordic’s Gel Pack Conditioning Program, logistics managers gain a dependable framework for vaccine protection that ensures each shipment arrives ready to protect the lives it was intended to serve.