Shipping desserts, whether delicate confections, rich chocolates, or artisanal pastries, requires more than efficient logistics. These temperature-sensitive products are uniquely vulnerable to spoilage, bloom, melting, and structural degradation when exposed to thermal fluctuations. Preserving quality through transit demands a meticulously controlled cold chain where refrigerants, insulation, packaging design, and transit timing all work in harmony to maintain the integrity of every item.

As demand for gourmet and specialty sweets rises across direct-to-consumer and wholesale channels, dessert brands must ensure flawless delivery despite environmental and logistical challenges. Temperature stability is no longer a luxury but a brand imperative. This guide explores the essential elements of a high-performance cold chain tailored to desserts, providing strategies for confectioners, eCommerce platforms, and logistics partners dedicated to delivering uncompromised quality.

The Cold Chain Challenge in Dessert Logistics

Desserts present unique challenges to cold chain logistics. Unlike frozen commodities that can tolerate a broad range of sub-zero temperatures, many confections must be maintained within narrow thermal windows to preserve texture, appearance, and flavor. For example, chocolate begins to melt at around 86°F (30°C), and exposure to fluctuating temperatures can cause fat or sugar bloom. This results in white streaks, dull surfaces, and degraded mouthfeel. Delicate items like gelato, mousse, or cheesecake may lose structure, collapse, or suffer irreversible textural changes if not carefully protected.

Cold chain for confections must therefore be tightly controlled from production through last-mile delivery.

This includes:

- Stable cooling throughout transit

Refrigerated or insulated systems must maintain a consistent temperature range (typically between 2°C and 20°C) depending on the dessert type. Even short temperature spikes during handling can lead to melting or textural degradation. - Protection from ambient heat and humidity

Packaging must shield products from external heat and moisture, especially in warm climates. High insulation is critical to prevent spoilage and moisture buildup that can affect both safety and appearance. - Packaging that prevents condensation and vibration

Effective insulation and cushioning help minimize movement and moisture. Without proper controls, condensation can compromise finishes, while vibration can distort delicate desserts in transit. - Consistent communication with logistics partners and carriers

Clear handling instructions and trained partners reduce risk. Temperature monitoring and alerts enable fast action if a shipment veers outside acceptable conditions.

Failure to manage these variables does not merely risk product loss. It undermines brand credibility and customer satisfaction. In a market where presentation, mouthfeel, and freshness define value, even a minor cold chain lapse can trigger customer complaints, increase return rates, and reduce long-term loyalty. Cold chain strategy for confections must therefore be proactive, data-driven, and tailored to the specific fragility of sweet goods in transit.

Precision Thermal Packaging for Desserts

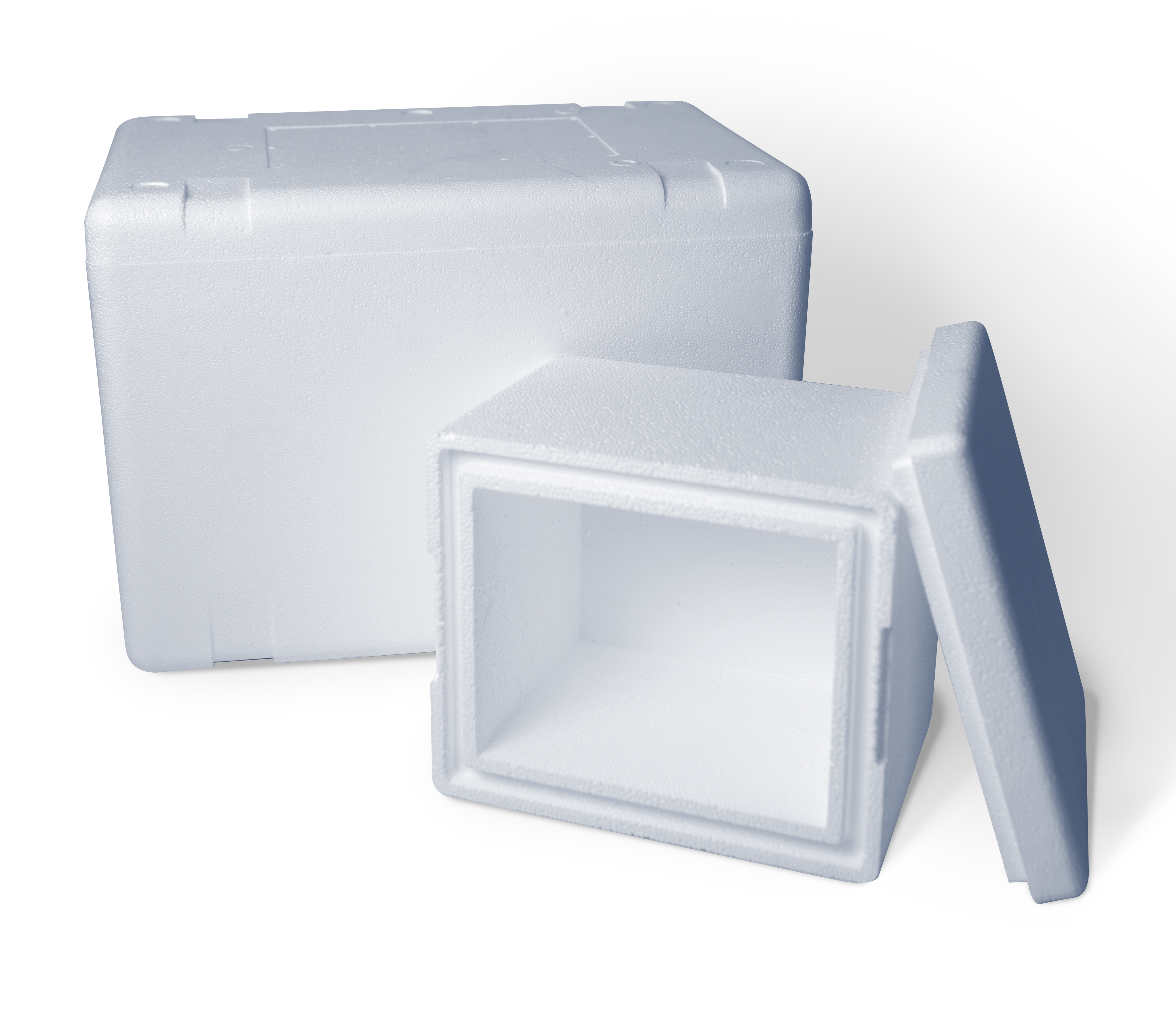

The foundation of any reliable cold chain for desserts is its thermal packaging system. Nordic Cold Chain Solutions has engineered a wide array of options suited for both ambient-protective and frozen shipments. Their EPS (expanded polystyrene) shipping coolers provide high insulation for 24 to 48 hour parcel durations, making them ideal for delicate confections shipped via ground or express services. These coolers are designed to maintain internal stability, even in fluctuating external temperatures.

Key packaging features include:

- High R-value insulation to minimize temperature exchange with the external environment

Nordic’s EPS and PUR materials are engineered to maintain critical temperature thresholds, helping to prevent melt or bloom during prolonged transit or unexpected delays. - Durability to withstand handling and prevent compression of contents

Structural integrity is essential for preserving presentation. Nordic’s packaging resists crushing under load, protecting products from deformation or impact damage during warehouse processing and last-mile delivery. - Custom sizing and inserts for snug product fit, reducing movement and surface damage

Tailored inserts and cavity molds prevent internal shifting, which is especially important for items like macarons, chocolate truffles, or decorated pastries that can crack or smudge with minimal movement. - Moisture barriers to prevent condensation buildup on product surfaces

Integrated vapor barriers and lining materials reduce the risk of condensation that can cause soggy textures, loosened packaging, or the smearing of chocolate finishes and printed decorations.

For brands shipping high volumes or distributing through wholesale channels, Nordic offers scalable logistics solutions designed to preserve product quality at every stage. These systems are compatible with a range of refrigerants and gel packs, allowing for customized configurations that maintain thermal consistency throughout transit. Whether fulfilling national retail orders or supporting regional distribution centers, these solutions help dessert brands ensure that delicate products arrive intact, fresh, and ready for presentation.

Gel Packs: The Refrigerant Backbone

For confections that require a controlled cool environment, where freezing would compromise texture and flavor, gel packs offer the ideal thermal solution. Unlike dry ice, which can cause cracking, hardening, or freezer burn, gel packs offer a stable, moderate cooling effect that protects the structural and sensory integrity of temperature-sensitive sweets. They are particularly well-suited for items like fudge, truffles, and iced pastries, which require precision in thermal management but cannot tolerate extreme cold. Additionally, gel packs allow for more flexible shipping options, as they do not carry the same regulatory restrictions as dry ice and are safer to handle throughout the supply chain.

Nordic Cold Chain Solutions produces a range of high-performance gel packs tailored to confectionery shipping.

Key considerations when selecting gel packs include:

- Freeze temperature profile

Gel packs must be conditioned to the appropriate range prior to use—typically 2–8°C for perishable desserts or 15–25°C for heat-sensitive chocolates. Selecting the correct phase-change temperature ensures consistent protection without risking textural compromise or overcooling. - Shape and stacking profile

Nordic’s flat-freeze design allows packs to freeze uniformly, maintaining a consistent thickness that optimizes payload space and thermal contact. This reduces voids and prevents uneven cooling that can lead to localized melt or bloom. - Durability and leak resistance

Premium gel packs are engineered with multi-layer films and heat-sealed seams to withstand rough handling, pressure changes, and repeated contact with products. This durability minimizes the risk of leaks that can damage both the product and its packaging. - Sustainability

Nordic offers gel packs made from curbside-recyclable materials and biodegradable gel formulas. These reduce landfill burden and support corporate sustainability initiatives without compromising thermal performance or safety.

Strategic placement of gel packs, whether above, below, or surrounding the product, plays a critical role in maintaining consistent internal temperatures. Placement should be guided by heat flow dynamics, product sensitivity, and transit duration. As active components of the cold chain, gel packs influence shelf life, visual presentation, and product safety. By selecting the right type and positioning based on validated pack-out procedures, dessert brands can reduce thermal risk and ensure quality from shipment to delivery.

From Compliance to Confidence: Strengthening Your Dessert Cold Chain

Dessert shipping operates at the intersection of food safety regulation, brand stewardship, and customer experience. Products distributed across regional, national, or international markets must meet stringent food safety standards, including proper labeling, material safety for food contact, and adherence to time-temperature controls. Even a single lapse in protocol can lead to compromised product integrity, lost revenue, and reputational damage.

Partnering with a cold chain provider like Nordic ensures that dessert brands remain protected at every level. Their solutions are backed by validated performance testing, full compliance with USDA, FDA, and state-level transport regulations, and audit-ready documentation for quality assurance. With over 50 manufacturing and distribution centers across the U.S., Nordic provides the infrastructure needed for responsive scaling and regionally optimized fulfillment.

In the high-stakes world of premium confections, the cold chain is not a background process. It is a strategic driver of product excellence. Nordic Cold Chain Solutions delivers more than thermal protection. With precision-engineered packaging, advanced refrigerants, and industry-specific expertise, Nordic helps dessert brands ship with confidence and consistency. Every product arrives as it was crafted: fresh, flawless, and ready to impress.