The Challenges of Pharmaceutical Cold Chain Logistics

Pharmaceutical cold chain logistics present unique challenges. Many pharmaceutical products—such as vaccines, biologics, and certain medications—must be kept within a narrow temperature range to preserve their integrity and effectiveness. Even minor deviations from these required conditions can compromise product quality, potentially rendering life-saving treatments ineffective or unsafe.

Regulatory bodies, including the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have established strict pharmaceutical cold chain management guidelines. These regulations ensure that products are handled, transported, and stored in conditions that maintain safety and potency.

The complexity of pharmaceutical cold chain logistics extends beyond maintaining temperature. Varying climates, long-distance transport, and multiple handovers across the supply chain introduce the risk of temperature fluctuations. Ensuring that our packaging solutions can withstand these environmental challenges is crucial for keeping pharmaceutical products safe and effective.

Best Practices for Cold Chain Packaging

Adopting best pharmaceutical cold chain packaging practices is essential to overcoming these challenges. By selecting and designing packaging that meets industry standards, we ensure products are delivered safely and compliant with regulatory requirements.Validated Packaging Solutions

Cold chain packaging must be validated to maintain the required temperature range under real-world conditions. Validation involves rigorous testing to confirm that our packaging can withstand temperature fluctuations, vibrations, and humidity changes across the supply chain. With validated packaging solutions, we give pharmaceutical companies confidence that their products will remain safe, even when faced with external stresses.At Nordic Cold Chain, we specialize in providing validated packaging systems designed to meet the specific requirements of pharmaceutical products. Our solutions offer consistent temperature control during transit, ensuring the safety and efficacy of the transported medications.

Qualified Insulation Materials

Insulation is key to controlling the temperature within the packaging. High-quality insulation materials reduce heat transfer between the external environment and the package’s contents, helping maintain the required temperature. We use insulation materials for pharmaceutical applications that offer reliability and consistency, minimizing performance variability.

Insulation is key to controlling the temperature within the packaging. High-quality insulation materials reduce heat transfer between the external environment and the package’s contents, helping maintain the required temperature. We use insulation materials for pharmaceutical applications that offer reliability and consistency, minimizing performance variability.

At Nordic Cold Chain, we offer packaging equipped with qualified insulation materials that are proven to maintain temperature stability during transit. Our insulation solutions are designed for various shipping needs, whether the products travel domestically or globally.

Temperature Monitoring Systems

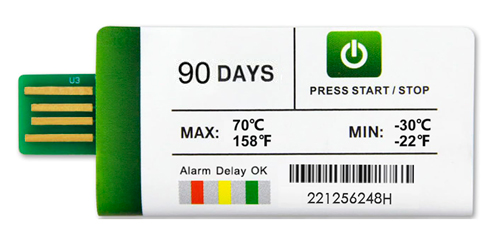

Temperature monitoring is essential for tracking conditions inside the packaging throughout the entire supply chain. These systems allow logistics managers to verify that products remain within the required temperature range during transit. If a deviation occurs, corrective actions can be taken immediately to protect product safety.

Temperature monitoring is essential for tracking conditions inside the packaging throughout the entire supply chain. These systems allow logistics managers to verify that products remain within the required temperature range during transit. If a deviation occurs, corrective actions can be taken immediately to protect product safety.

At Nordic Cold Chain, we integrate temperature monitoring systems, such as data loggers and real-time sensors, into our packaging designs. These systems provide valuable data to ensure that pharmaceutical companies can track and maintain the integrity of their shipments and take immediate action if needed.

Secure Packaging Materials

Pharmaceutical products require secure packaging that protects against physical damage, tampering, or contamination during transit. At the same time, packaging must remain lightweight and efficient to minimize shipping costs. Balancing these needs is a key consideration in cold chain packaging.Our packaging solutions at Nordic Cold Chain are designed with security in mind. We use durable materials that protect the sensitive pharmaceuticals inside and comply with regulatory standards. Our secure packaging helps ensure that products remain intact and protected throughout the supply chain.

How We Tailor Solutions at Nordic Cold Chain

At Nordic Cold Chain, we understand the critical role packaging plays in pharmaceutical cold chain logistics. Our tailored solutions are designed to meet the unique needs of pharmaceutical companies, ensuring that temperature-sensitive products are delivered safely and efficiently. By offering validated packaging, qualified insulation, advanced temperature monitoring systems, and secure materials, we help our clients navigate the complexities of the cold chain while staying compliant with industry regulations.

At Nordic Cold Chain, we understand the critical role packaging plays in pharmaceutical cold chain logistics. Our tailored solutions are designed to meet the unique needs of pharmaceutical companies, ensuring that temperature-sensitive products are delivered safely and efficiently. By offering validated packaging, qualified insulation, advanced temperature monitoring systems, and secure materials, we help our clients navigate the complexities of the cold chain while staying compliant with industry regulations.

Our commitment to innovation and quality drives us to provide packaging solutions that meet and exceed industry standards. Whether you’re shipping vaccines, biologics, or other temperature-sensitive medications, our systems are built to maintain product integrity and safety throughout the supply chain.

The Importance of Reliable, Compliant Packaging

Reliable and compliant packaging is essential—not just for regulatory reasons but to ensure the safety and efficacy of pharmaceutical products. The importance of effective cold chain practices cannot be overstated as the pharmaceutical industry evolves to meet the demands of global distribution, regulatory compliance, and environmental sustainability. At Nordic Cold Chain, we are committed to providing proven, reliable packaging solutions that meet these challenges head-on.

Reliable and compliant packaging is essential—not just for regulatory reasons but to ensure the safety and efficacy of pharmaceutical products. The importance of effective cold chain practices cannot be overstated as the pharmaceutical industry evolves to meet the demands of global distribution, regulatory compliance, and environmental sustainability. At Nordic Cold Chain, we are committed to providing proven, reliable packaging solutions that meet these challenges head-on.