When shipping products that must be kept at a specific temperature, one of the most common yet overlooked solutions is cold chain packaging. From keeping food fresh to pharmaceuticals safe and temperature-sensitive, the proper cold chain packaging can make all the difference in delivering quality goods on time, no matter where they’re headed. Today, we will discuss some popular types of cold chain packaging and their benefits and considerations for use in your shipping operation.

Common Cold Chain Packaging Solutions

Selecting the right cold chain packaging solution is critical for products that require precise temperature regulation throughout their shipping journey. From insulation and advanced cooling systems to climate-controlled containers, various options are available for keeping your goods at ideal temperatures. Take a look at these four common selections – each designed with safety and efficiency in mind!

-

Shippers: Shippers are essentially boxes designed with an insulated liner that allows for the safe transport of perishable items. They are usually made from expanded polystyrene (EPS) material which keeps its temperature for long periods of time even when exposed to high temperatures outside the box. Depending on your needs, these boxes can be adapted to different sizes and shapes and work great when transporting pharmaceuticals or food-grade items like milk or ice cream.

Shippers: Shippers are essentially boxes designed with an insulated liner that allows for the safe transport of perishable items. They are usually made from expanded polystyrene (EPS) material which keeps its temperature for long periods of time even when exposed to high temperatures outside the box. Depending on your needs, these boxes can be adapted to different sizes and shapes and work great when transporting pharmaceuticals or food-grade items like milk or ice cream. Gel packs: Gel packs help keep refrigerated or frozen items cool during transit by absorbing thermal energy inside the package via phase change technology. These gel packs come in various sizes ranging from small sachets that fit inside regular cardboard packages to large total void fill containers used as standalone inserts. They are available as pre-made forms filled with various fluids, including methanol, water, glycol, and more, depending on what type of product needs cooling down during transportation built into them – making them very versatile solutions for many applications where cold chain protective environments are required.

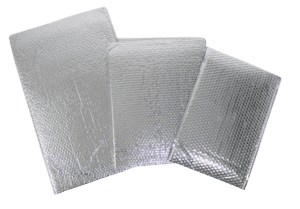

Gel packs: Gel packs help keep refrigerated or frozen items cool during transit by absorbing thermal energy inside the package via phase change technology. These gel packs come in various sizes ranging from small sachets that fit inside regular cardboard packages to large total void fill containers used as standalone inserts. They are available as pre-made forms filled with various fluids, including methanol, water, glycol, and more, depending on what type of product needs cooling down during transportation built into them – making them very versatile solutions for many applications where cold chain protective environments are required. Insulated mailers: Insulated mailers provides excellent barriers against heat transfer while being lightweight at the same time due to their multiple layers construction which usually consists of bubble wrap suspended between two air bubble liners around an interior padding layer such as styrofoam pellets or batting material surrounded by a four-ply foam insulation board core layer around all sides – making these mailers very effective against warm temperatures without adding too much weight in comparison with other options like styrofoam coolers which could cause shipping costs to skyrocket.

Insulated mailers: Insulated mailers provides excellent barriers against heat transfer while being lightweight at the same time due to their multiple layers construction which usually consists of bubble wrap suspended between two air bubble liners around an interior padding layer such as styrofoam pellets or batting material surrounded by a four-ply foam insulation board core layer around all sides – making these mailers very effective against warm temperatures without adding too much weight in comparison with other options like styrofoam coolers which could cause shipping costs to skyrocket. Pallet shippers: Pallet shippers help protect goods from damage during distribution via pallets; they offer protection from shocks/vibrations & also maintain temperature control through their use of expanded polystyrene corrugated walls surrounding either one large cavity filled with chilled air (like RTC’s PGC) or multiple smaller cells separated by plastic partitions providing separate individual compartments hold different products at different temperatures simultaneously.

Pallet shippers: Pallet shippers help protect goods from damage during distribution via pallets; they offer protection from shocks/vibrations & also maintain temperature control through their use of expanded polystyrene corrugated walls surrounding either one large cavity filled with chilled air (like RTC’s PGC) or multiple smaller cells separated by plastic partitions providing separate individual compartments hold different products at different temperatures simultaneously.

Why Cold Chain Packaging is so Important

Cold chain packaging is essential in distributing perishable products, such as food, medical supplies, and vaccines. It involves keeping a constant temperature from when it is produced to when it is consumed to maintain freshness and minimize spoilage. Without cold chain packaging, these products would be at risk of spoiling or becoming unsafe for consumption by the time they reach their destination.

Without cold chain packaging, several dangers could occur due to improper storage temperatures during transporting and handling of delicate items like food or pharmaceuticals. These include the growth of potentially harmful microorganisms like bacteria and fungi leading to a decrease in quality as well as causing food poisoning; changes in product properties leading to unappealing textures or tastes; loss of activity through oxidation reactions; nutritional value decreasing due to vitamin degradation; altered appearance making it difficult for consumers to recognize brands; susceptibility of some materials prone to breaking down under higher temperatures etc.

Also, not having proper refrigeration systems can lead to a drastic increase in energy costs due to inefficient cooling methods while also increasing the risk of damaging ordinary containers filled with sensitive commodities, which can lead to hundreds of thousands if not millions worth of revenue lost from potential damages caused by liquids leaking inside cargo ships -causing further delay on delivery times- or rejection on deliveries due temperature breaches set out by government regulations for certain type commodities (e.g., dairy products).

In addition to keeping goods safe during transport, cold chain packaging also helps maintain consistency so consumers will always get top-quality products regardless of how long ago they were produced. This ensures that all products reach their destination with the same attributes they left with – color, taste/smell, nutritional content, etc.

Final thoughts

Maintaining the integrity of a cold chain is essential to providing safe and fresh products to customers. The packaging solutions available for businesses seeking to improve their cold chain processes are vast. Careful considerations must be taken when evaluating which packaging components should be used to ensure the product travels safely. Nordic Cold Chain Solution can offer reliable guidance in making your product’s journey through a successfully managed cold chain system as easy and efficient as possible.

Whether you prefer robust crating for large loads or innovative temperature control technology for precise shipments, Nordic Cold Chain Solutions covers your needs!