From farm-fresh produce to ready-to-eat meals, the cold chain for food logistics depends on packaging systems that preserve both product quality and consumer confidence. Every shipment is more than a simple transfer of goods. It is a carefully orchestrated process in which temperature stability, moisture control, and physical protection determine whether food arrives in peak condition or is lost to spoilage. In an era where efficiency and safety are paramount, the ability to protect delicate products throughout their journey is a defining advantage for food suppliers and distributors.

At the same time, packaging is being judged not only on performance but also on its environmental impact. Businesses are under increasing pressure to demonstrate sustainable practices without sacrificing reliability. Consumers and retailers alike are scrutinizing how products are packaged, transported, and ultimately disposed of. Balancing cold chain precision with ecological responsibility has become a central challenge, and Nordic Cold Chain Solutions is addressing this need through gel packs, insulated foil bubble liners, and durable cooler boxes engineered to safeguard freshness while reducing waste.

The Challenges of Fresh Food Shipping

Unlike frozen products that can be held at consistently subzero temperatures, fresh food requires careful thermal management. Produce, prepared meals, and specialty foods must be protected against heat intrusion and dehydration while remaining visually appealing and safe to consume. Any lapse in protection can lead to shortened shelf life, quality degradation, and costly losses. The challenge is magnified by the variability of transit conditions, ranging from local grocery deliveries to multi-day distribution across regions.

This complexity demands packaging solutions that adapt to specific shipping scenarios. Nordic’s gel packs, foil bubble liners, and polyurethane cooler boxes are designed not as generic containers but as integral components of a comprehensive cold chain strategy.

Gel Packs: Precision in Temperature Control

At the core of many fresh food packaging systems are gel refrigerant packs. These flexible solutions offer a controllable method for keeping products cool without the complexity of mechanical refrigeration. Nordic has led innovation in gel pack technology for over fifteen years, offering a portfolio that supports the unique requirements of food shippers.

Versatile Options for Every Product

Our Nordic Ice® Gel Refrigerant Packs provide durable, reusable cooling power for a wide range of products. Available in multiple sizes, they can be customized to fit small produce boxes, large meal kits, or specialty deliveries. For moisture-sensitive applications, our No Sweat options ensure labels and packaging remain free of condensation. Gift baskets, branded meal subscriptions, and delicate baked goods all benefit from the clean presentation that No Sweat packs make possible.

Sustainability in Practice

Nordic Drain Safe® Gel Packs are the first of their kind to be approved for disposal in municipal wastewater and septic systems. This innovation offers customers an environmentally friendly alternative to traditional refrigerants, reducing the burden of packaging waste while still ensuring reliable cooling performance. Linked gel packs further enhance efficiency by offering flat, connected segments that maximize packing density and space utilization.

Applications in Fresh Food Shipping

Gel packs play a central role in extending the shelf life of produce, dairy, seafood, and ready-to-eat meals during last-mile delivery. Whether used on their own or in combination with liners or cooler boxes, they ensure consistent temperatures that guard against premature spoilage and preserve sensory quality.

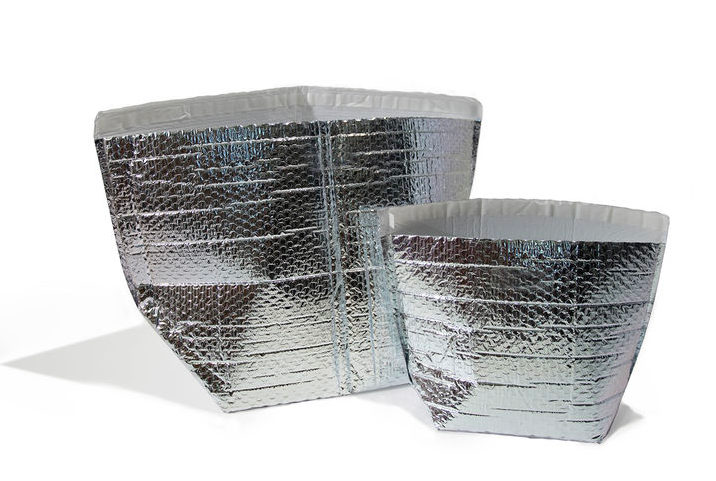

Insulated Foil Bubble Liners: Flexible, Cost-Effective Protection

For shipments with shorter transit times, insulated foil bubble box liners provide a cost-effective layer of protection. Constructed from reflective foil and bubble material, these liners are engineered to reduce radiant heat transfer and minimize temperature excursions.

Key Performance Advantages

Nordic’s foil bubble liners are leak-resistant and feature a nylon barrier that prevents odor transfer, allowing products with strong flavors to ship alongside sensitive items without cross-contamination. The reflective shell further enhances thermal protection by deflecting external heat. Their collapsible design allows for easy storage, handling, and disposal, making them a practical choice for businesses shipping high volumes of food within 24 hours.

Ideal Use Cases

These liners are best suited for regional shipments, grocery deliveries, or subscription services with one-day transit commitments. When paired with gel packs, they create a protective micro-environment that can handle both ambient and chilled conditions. The result is a shipping system that balances performance with cost and sustainability.

Sustainability Considerations

Foil bubble liners are lightweight, reducing overall shipping weight and associated emissions. Because they are easy to dispose of and resistant to cracking, they minimize customer frustration while still supporting temperature-controlled logistics.

Cooler Boxes: Long-Haul Assurance

When shipments must travel longer distances or remain in transit for extended periods, polyurethane cooler boxes provide the necessary durability and insulation performance. These two-part systems, consisting of a molded polyurethane box encased in a corrugated shell, combine thermal efficiency with physical protection.

Superior Insulation Properties

Polyurethane has a lower thermal conductivity than expanded polystyrene, giving cooler boxes the ability to maintain consistent temperatures over extended durations. This makes them particularly valuable for cross-country or international shipments where fresh food must endure multiple handling points and variable climates.

Protection Beyond Temperature

The corrugated exterior of Nordic’s cooler boxes shields sensitive products from crushing or impact damage during shipping. This structural resilience ensures that food arrives not only fresh but also visually intact, an important consideration for retail presentation and consumer satisfaction.

The corrugated exterior of Nordic’s cooler boxes shields sensitive products from crushing or impact damage during shipping. This structural resilience ensures that food arrives not only fresh but also visually intact, an important consideration for retail presentation and consumer satisfaction.

Customization and Flexibility

Available in a range of standard sizes and fully customizable for unique product dimensions, cooler boxes give businesses the flexibility to scale packaging to their operational needs. Whether shipping small artisanal goods or large pallets of produce, Nordic experts can design configurations that minimize waste while maximizing performance.

Integrating Gel Packs, Liners, and Cooler Boxes

The strength of Nordic’s approach lies not only in individual products but in the ability to combine them into tailored solutions. For example, a regional meal kit provider might pair foil bubble liners with Drain Safe® Gel Packs for cost-effective one-day delivery. A national seafood distributor, by contrast, may rely on polyurethane cooler boxes supplemented with reusable gel packs to ensure freshness across multiple transit days. The adaptability of these solutions allows businesses to optimize packaging for both operational efficiency and sustainability goals.

Building Trust and Safeguarding Freshness

At the heart of fresh food shipping is trust. Retailers and consumers alike expect products to arrive in peak condition, and packaging that fails to protect against spoilage or damage risks not only immediate financial loss but long-term reputational harm. Nordic Cold Chain Solutions understands these stakes, which is why our gel packs, insulated foil bubble liners, and polyurethane cooler boxes are engineered with precision to provide consistent protection across every shipment.

Fresh food shipping is a balance of science, engineering, and responsibility. Gel packs deliver precise temperature control, liners offer lightweight and flexible insulation, and cooler boxes provide the durability required for extended transit. Together, these solutions preserve freshness, reduce waste, and meet the evolving expectations of both consumers and regulators. As the demand for farm-to-table produce, ready-to-eat meals, and specialty foods continues to rise, businesses need partners who can match quality with reliability. Nordic Cold Chain Solutions is proud to be that partner, safeguarding product integrity while supporting sustainable logistics.