Preserving the integrity of frozen goods, whether artisanal pastries, high-grade meats, or delicate prepared meals, requires far more than temperature maintenance. These products demand a packaging system that provides both thermal reliability and robust physical protection. Nordic Cold Chain Solutions addresses this need with multi-layered designs that unite insulation and structural durability to create a shipping environment optimized for both temperature control and mechanical resilience.

Within the frozen food supply chain, temperature regulation is only part of the equation. Equally critical, yet frequently overlooked, is the ability to safeguard against physical stress. Vibration, compression, impact, and environmental fluctuations can compromise product quality long before thermal thresholds are breached. For frozen items with high sensitivity and commercial value, a single-layer thermal solution is insufficient. Only a comprehensive, multi-component system can guarantee that these products reach their destination in uncompromised condition.

Nordic Cold Chain Solutions delivers this assurance through a rigorously engineered portfolio of packaging technologies. Each system integrates advanced insulation, shock-absorbing architecture, and structural reinforcement into a unified defense. These are not passive containers. They are precision-built systems designed to shield temperature-sensitive goods from both heat and harm.

Redefining Integrity in Frozen Food Packaging

The traditional approach to frozen food logistics has centered on insulated containers, often expanded polystyrene or similar materials, paired with coolant packs. While these systems are effective at maintaining internal temperatures, they provide limited resistance to mechanical stress during handling, transit, and last-mile delivery. As consumer expectations rise and distribution networks grow more complex, product protection must be multidimensional. Effective packaging must now account not only for thermal insulation, but also for vibration damping, structural integrity, and environmental exposure throughout the shipping lifecycle.

The traditional approach to frozen food logistics has centered on insulated containers, often expanded polystyrene or similar materials, paired with coolant packs. While these systems are effective at maintaining internal temperatures, they provide limited resistance to mechanical stress during handling, transit, and last-mile delivery. As consumer expectations rise and distribution networks grow more complex, product protection must be multidimensional. Effective packaging must now account not only for thermal insulation, but also for vibration damping, structural integrity, and environmental exposure throughout the shipping lifecycle.

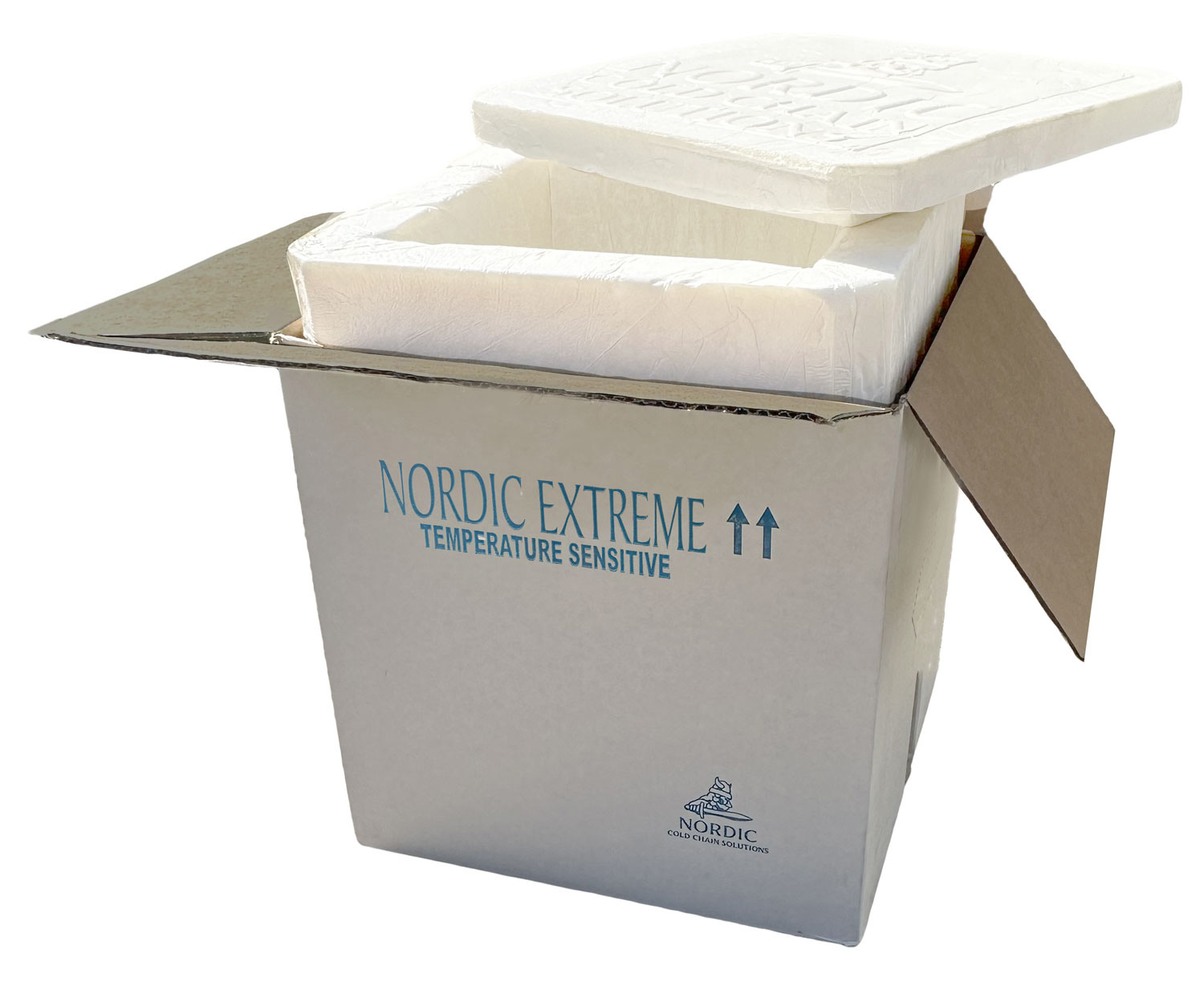

Multi-component packaging systems function as integrated defense mechanisms engineered to address both thermal and mechanical vulnerabilities. At Nordic, this begins with precision-molded thermal enclosures such as the Nordic Extreme PUR Frozen Shipper. These units employ rigid polyurethane insulation to sustain sub-zero temperatures over extended transit durations. Encapsulating the thermal core is a structurally reinforced corrugated exterior, engineered to dissipate shock and mitigate compressive forces encountered during distribution. This dual-structure configuration ensures thermal uniformity within the payload cavity while providing a mechanical barrier against impact and environmental stress.

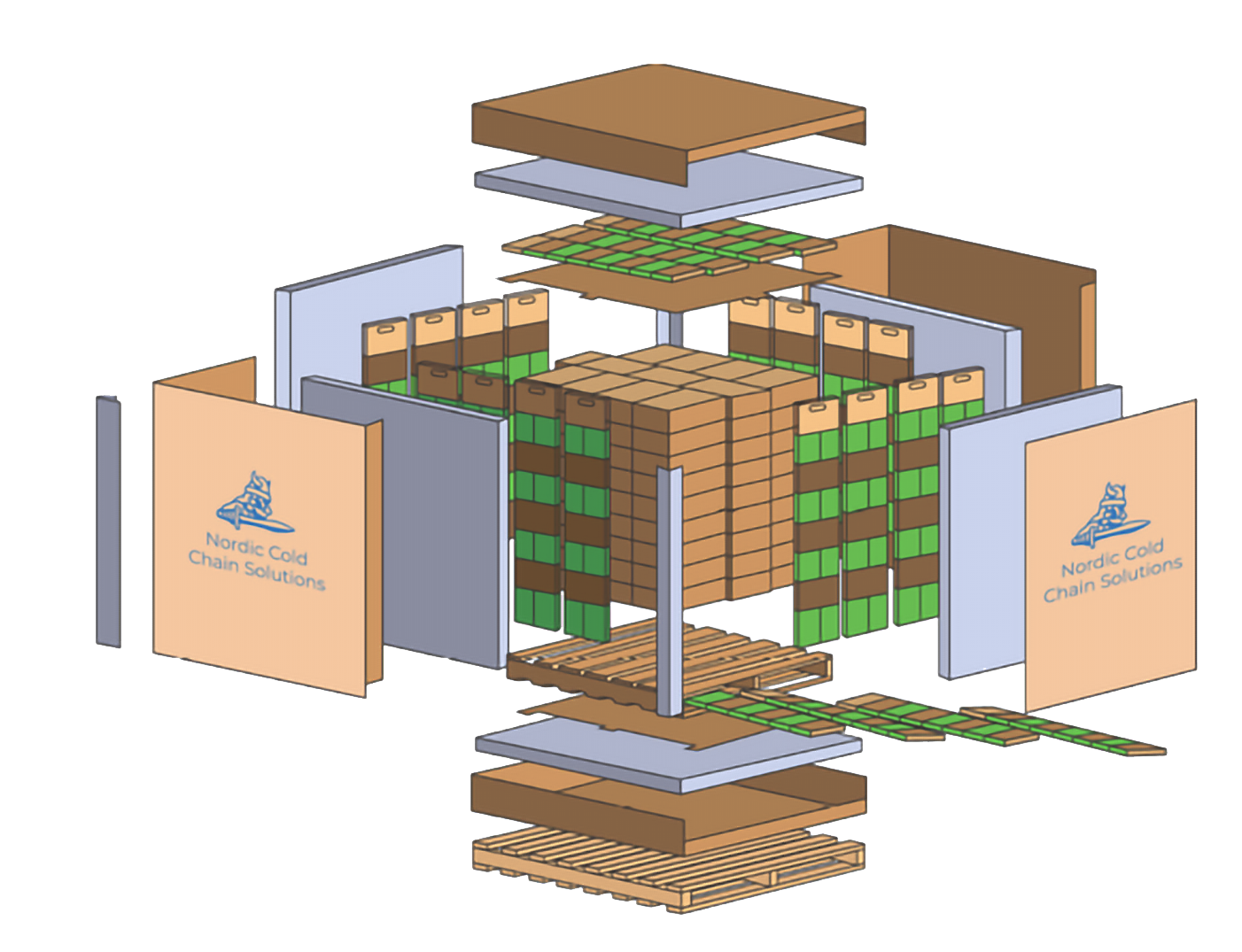

For shipments requiring high payload capacity, Nordic offers the 1800 CRT Pallet Shipper, a precision-designed solution for large-scale food freight. Built to fit standard air freight configurations (PMC/LD7), this shipper ensures thermal protection over five or more days and integrates seamlessly into international shipping infrastructure. Its structural integrity accommodates stacking and mechanical handling without compromising the internal payload, making it ideal for bulk frozen food logistics.

The Role of Gel Packs in Shock-Resistant Cold Chain Solutions

At the heart of thermal protection is the coolant system, and Nordic’s Ice® Regular Gel Packs have set the industry benchmark for consistency, performance, and durability. Engineered for precision cooling, these gel packs are formulated to maintain strict sub-zero thresholds for extended periods. Beyond thermal control, their dense polymer gel matrix and rugged polyethylene casing provide a secondary function: mechanical shock absorption. When deployed within a multi-component system, they serve as both active thermal agents and passive protective buffers.

When integrated into optimized pack-outs, Nordic Ice® Gel Packs deliver critical dual functionality:

- Temperature regulation, sustaining frozen conditions consistently across 1- to 3-day transit windows, even in fluctuating external environments

- Impact damping, mitigating product movement, vibration, and localized pressure during long-haul or last-mile logistics

- Leak-resistant construction, featuring sealed high-density film that resists punctures and prevents coolant exposure to primary packaging

- Reusable design, made with long-lasting polymer gel that retains structural integrity over multiple freeze-thaw cycles, ideal for repeat-use lanes or circular supply chains

- Void space reduction, allowing gel packs to be strategically positioned to reduce air pockets that compromise insulation performance and increase internal temperature variability

This dual-role capability significantly enhances overall cold chain resilience. By delivering both thermal stability and mechanical protection in a single element, gel packs contribute to packaging efficiency while reducing the risk of shipment failure. When paired with Nordic’s rigid polyurethane containers and outer corrugate structures, they help create a comprehensive cold chain solution capable of withstanding real-world transport conditions without compromising payload integrity.

Designed to Withstand High-Stress Logistics Conditions

Frozen food products do not move through controlled or predictable environments. They are subjected to a range of physical and thermal stressors as they pass through air cargo terminals, over-the-road freight systems, last-mile distribution centers, and various climate zones. Each phase introduces potential hazards such as mechanical shock, pressure loading, temperature excursions, and condensation exposure. Nordic’s packaging systems are specifically designed to withstand these multifactorial logistics conditions, not just laboratory-controlled scenarios.

The Nordic Extreme PUR Shipper is ISTA 7E tested, proving performance in distribution conditions that simulate the most demanding transit realities:

- Drop testing, modeling vertical and angular impacts caused by manual handling, conveyor transfer, and pallet jostling

- Compression testing, evaluating structural integrity under dynamic load stacking, including uneven weight distribution during air and ground transport

- Thermal cycle testing, simulating external environmental shifts to assess insulation stability across hot tarmac exposure, cold storage intervals, and fluctuating warehouse temperatures

The tri-layer system is purpose-built to preserve frozen payloads during prolonged, high-friction transit:

- Corrugated outer shell, designed for crush resistance and water repellency, providing a first line of defense against abrasion, impact, and external contaminants

- Polyurethane insulation core, offering superior thermal resistance with low thermal conductivity (λ-value), capable of maintaining sub-zero conditions for over 72 hours

- Modular coolant system, including gel packs or dry ice, configured based on shipment volume, duration, and destination-specific ambient risk profiles

Together, these elements form a closed-loop thermal and mechanical protection system that is resilient under real transport conditions, not just controlled simulations. This systems-level approach ensures that product integrity is preserved across the entire distribution chain, from origin to end recipient. It accounts for route complexity, carrier variability, and environmental volatility. For food distributors, it means fewer rejected deliveries, tighter compliance with food safety regulations, and sustained product quality under operational pressure.

Scalable Solutions with Proven Protection

Multi-component packaging is not a one-size-fits-all solution. Frozen food products vary in their sensitivity to temperature, impact, vibration, and moisture exposure, requiring tailored configurations to ensure consistent protection. Nordic Cold Chain Solutions addresses this variability with a full spectrum of scalable systems, engineered to accommodate both high-volume and regional distribution needs.

The 1800 CRT Pallet Shipper is optimized for full-pallet loads and international freight, offering robust protection for wholesale meal kits, frozen proteins, and large-format food shipments. For smaller payloads or regional distribution, Nordic’s PUR Frozen Shippers deliver the same multi-layered protection for delicate items such as desserts, seafood, or specialty frozen goods. Each system is designed to ship flat, assemble with minimal labor, and integrate smoothly into existing supply chains.

For brands in the frozen food sector, packaging plays a critical role as the final gatekeeper of product quality, not just as a means of transportation. Issues like frost damage, seal breaches, or temperature drift can compromise both safety and customer trust. Nordic’s packaging systems are engineered to prevent these failures through the precise calibration of every component, from coolant formulation to insulation thickness and corrugated strength.