Every blood sample, biopsy, or tissue specimen in transit carries more than biological material. It represents a potential life-saving transfusion, a key diagnostic result, or the foundation of groundbreaking medical research. Maintaining integrity during transport is not optional; it is a requirement that directly influences patient safety, research outcomes, and regulatory approval.

Blood and tissue shipments must remain within precisely defined temperature ranges throughout the supply chain. Even a brief deviation risks rendering a sample unusable, compromising not only the shipment itself but also the validity of medical decisions or research tied to it. Achieving this consistency requires packaging systems that combine reliable thermal performance with proven compliance.

Nordic Cold Chain Solutions specializes in providing frozen shippers and insulated packaging systems that deliver both. By designing solutions that protect against temperature excursions while meeting regulatory standards, Nordic ensures that every shipment has the best chance of arriving intact, viable, and compliant.

Meeting Stringent Regulatory Requirements

The transportation of blood and tissue is tightly regulated by organizations such as the American Association of Blood Banks (AABB), the U.S. Food and Drug Administration (FDA), and the European Directives on Blood and Tissues. These agencies outline detailed requirements for how biological materials must be stored, labeled, and transported. Non-compliance can have severe consequences, from shipment rejection to reputational damage for laboratories, hospitals, and research organizations.

Compliance requires more than just insulated packaging. Systems must be tested, validated, and documented to demonstrate performance under specific conditions. Nordic’s frozen shippers undergo rigorous ISTA 7E testing to prove their ability to maintain frozen conditions for one to three days in transit. This ensures that they not only meet but often exceed regulatory expectations for stability and reliability.

By choosing packaging solutions designed with compliance in mind, organizations reduce risk and build confidence that shipments will pass regulatory scrutiny.

Nordic Extreme PUR Frozen Shippers: Engineered for Performance

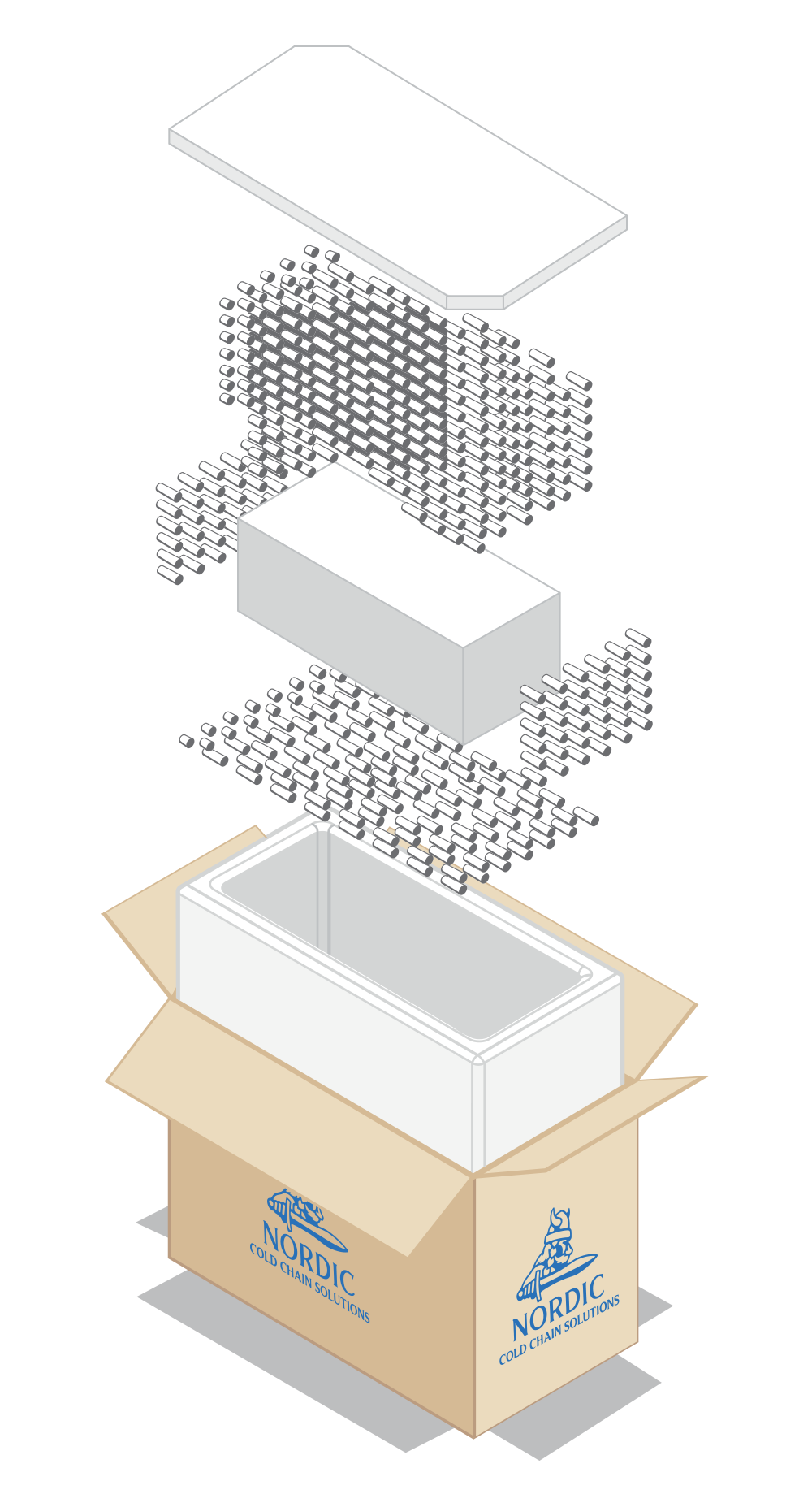

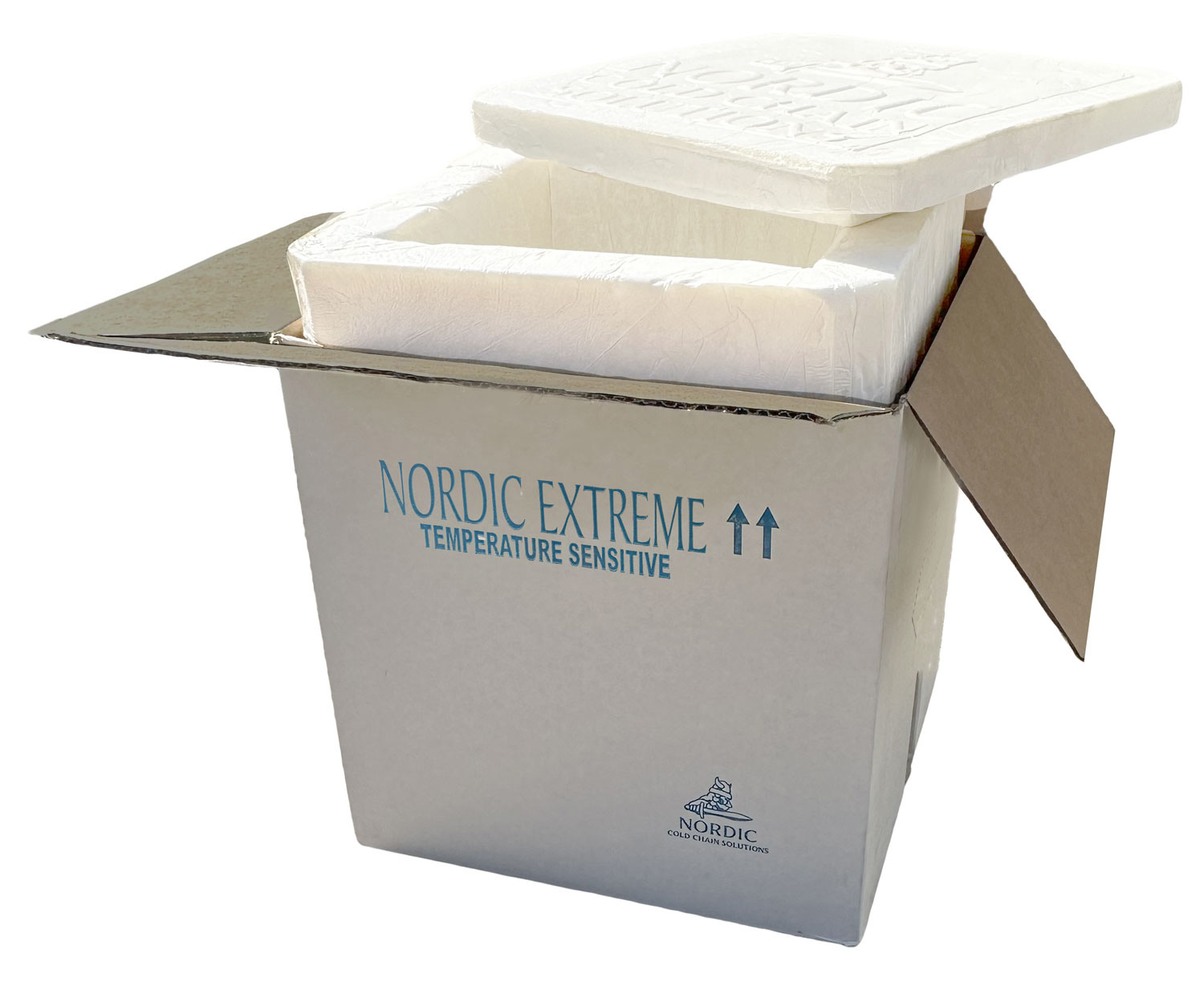

At the heart of Nordic’s compliance-ready portfolio are the Nordic Extreme PUR Frozen Shippers. These shippers are built using a multi-component system designed to withstand the most demanding medical logistics environments.

At the heart of Nordic’s compliance-ready portfolio are the Nordic Extreme PUR Frozen Shippers. These shippers are built using a multi-component system designed to withstand the most demanding medical logistics environments.

Polyurethane Insulation:

A high-performance expanded polyurethane core provides superior thermal resistance, maintaining frozen conditions even during long-haul or delayed transit.

Corrugated Exterior Protection:

Surrounding the insulation is a durable corrugated box that shields contents from impact, vibration, and external hazards.

Validated Performance:

Tested in Nordic’s on-site cold chain testing facility, these shippers are proven to maintain frozen temperatures for one to three days, depending on the configuration.

This dual-layer approach ensures that blood and tissue samples remain safe not only from thermal fluctuations but also from physical damage. For hospitals, diagnostic labs, and research facilities, this means shipments arrive in optimal condition without compromising compliance.

Why Reliability and Compliance Go Hand in Hand

In the medical cold chain, reliability is not just about protecting temperature ranges. It is also about ensuring that performance can be replicated, documented, and verified. A single shipment may be the subject of an audit or review, requiring detailed evidence that it was handled in accordance with regulations.

Nordic frozen shippers support this requirement by offering consistency. Each shipper is manufactured with precision, using high-quality materials that eliminate variability from one shipment to the next. Combined with optional monitoring and reporting tools, these systems create a transparent and traceable cold chain process.

For blood banks and tissue repositories, this means less uncertainty, fewer rejected samples, and stronger compliance records.

Safeguarding Sample Integrity Through Advanced Design

Blood and tissue are biologically sensitive materials that can degrade rapidly if exposed to thermal stress. Unlike pharmaceuticals, which often have buffers or stabilizers, biological samples demand stricter protection because their cellular structures or proteins may not recover from excursions.

Blood and tissue are biologically sensitive materials that can degrade rapidly if exposed to thermal stress. Unlike pharmaceuticals, which often have buffers or stabilizers, biological samples demand stricter protection because their cellular structures or proteins may not recover from excursions.

Nordic’s frozen shippers mitigate this risk through features such as:

- Even Thermal Distribution: Insulation and packout design minimize hot and cold spots, ensuring that every sample within a container receives uniform protection.

- Moisture and Condensation Control: Carefully engineered packouts prevent excess condensation, which could compromise packaging or contaminate samples.

- Durability Under Stress: The corrugated exterior resists crushing, punctures, and handling stress, reducing the risk of compromised containers during transit.

By addressing both thermal and physical vulnerabilities, Nordic ensures that integrity is preserved at every stage of the supply chain.

Cost-Effective Compliance Without Compromise

Meeting regulatory requirements does not have to come at the expense of operational budgets. Nordic’s frozen shippers are designed with cost-effectiveness in mind, providing high-performance packaging that reduces spoilage and reshipments.

When shipments are compromised, organizations face not only replacement costs but also delays in patient care, lost research opportunities, and reputational risk. Investing in packaging that ensures compliance minimizes these risks, making it a cost-effective choice over time.

Additionally, the durability of polyurethane systems reduces the need for frequent replacements, delivering long-term savings while maintaining uncompromised protection.

Supporting Clinical Trials and Research Programs

Clinical trials often involve transporting blood and tissue samples across long distances, sometimes internationally. In these scenarios, compliance and reliability become even more critical. A shipment compromised by thermal deviation or regulatory failure can invalidate trial data, delay approvals, and increase costs.

Nordic frozen shippers are particularly valuable in this context because they are:

- Validated for Long-Haul Performance: Proven to maintain frozen conditions across extended transit windows.

- Designed for Documentation: Packouts can be paired with real-time monitoring solutions, providing the visibility required for trial oversight and regulatory submission.

- Flexible Across Payloads: Available in multiple sizes to accommodate a wide range of sample volumes and formats.

For research institutions, this combination of performance and compliance helps ensure trial continuity and strengthens trust with regulators.

Building Confidence and Protecting What Matters Most

In today’s healthcare environment, confidence is as vital as compliance. Hospitals, research organizations, and blood banks must trust that their shipments will arrive uncompromised, and Nordic delivers this assurance by aligning packaging design with the highest industry standards. Using only the most reliable materials, supported by expert guidance and a proven track record in medical and pharmaceutical logistics, Nordic ensures durability, precision, and trust in every shipment.

This combination of advanced thermal protection and compliance-ready design allows organizations to focus on their mission of patient care and research while leaving the complexities of the medical cold chain in the hands of specialists. By safeguarding integrity, reducing risk, and meeting stringent regulatory requirements, Nordic frozen shippers protect life-saving materials and irreplaceable samples where failure is not an option.