As the market for GLP-1 medications such as Ozempic and Wegovy continues to grow, so does the responsibility placed on pharmacies, distributors, and logistics providers to ensure these sensitive biologics are delivered within strict temperature parameters. Even slight temperature deviations during transit can lead to reduced efficacy, compliance violations, and potential safety risks for patients. Maintaining control over every link in the cold chain is not just preferred—it’s mandatory.

To meet the specific demands of GLP-1 cold chain logistics, Nordic Cold Chain Solutions delivers a comprehensive suite of packaging innovations designed to ensure stability, traceability, and efficiency. From sustainable gel packs to advanced insulated shippers and real-time temperature monitoring, these technologies work in concert to protect the integrity of each dose—from the pharmacy to the patient’s door.

Gel Packs: A Sustainable Approach to Thermal Precision

At the heart of temperature-controlled packaging is the gel pack—a critical component in maintaining internal payload temperatures. However, not all gel packs are created equal, especially when shipping sensitive biologics like GLP-1 medications that require tight temperature control between 2°C and 8°C. Choosing the right gel pack is not only a matter of performance but also one of regulatory compliance, operational efficiency, and environmental responsibility.

Nordic® Ice-Eco Paper Gel Packs represent a breakthrough in pharmaceutical cold chain packaging. Designed to deliver either refrigerated or frozen temperature profiles, these gel packs provide thermal performance on par with traditional plastic-based options—without the environmental trade-offs. Their flat-freezing design allows for denser, more consistent packing configurations, while their 100% compostable gel interior and curbside-recyclable paper exterior make end-of-life disposal easy for pharmacies and patients alike.

Key benefits of Nordic® Ice-Eco Paper Gel Packs for GLP-1 shipments:

- Validated thermal performance

Proven to maintain stable internal temperatures for extended transit windows, even in variable ambient conditions, supporting temperature-sensitive GLP-1 therapies from fulfillment to final delivery. - Leak-proof and space-efficient

Engineered with advanced sealing technology to eliminate leakage risk, while the flat, stackable profile maximizes cube efficiency in insulated shippers and reduces overall freight volume. - Sustainability-first design

As the world’s first zero-waste gel pack, it features a biodegradable gel certified ASTM 6400 compostable and a recyclable paper exterior—helping reduce landfill waste and aligning with ESG goals.

In GLP-1 distribution, where regulatory scrutiny and patient safety intersect, these eco-conscious gel packs offer both peace of mind and a competitive advantage. They not only uphold the temperature integrity of highly sensitive medications, but also support brand trust, customer satisfaction, and long-term environmental commitments. As pharmacies and life sciences organizations scale to meet rising GLP-1 demand, choosing sustainable, performance-validated gel packs will be a critical differentiator.

Insulated Shippers: Layered Protection for Temperature Stability

For GLP-1 therapies that require extended transit times or pass through multiple temperature zones, basic insulation isn’t enough—consistent thermal protection is critical. Unlike shorter last-mile deliveries, these long-haul or high-variability shipping conditions demand insulation materials that can perform under sustained pressure. Nordic’s polyurethane cooler boxes are engineered specifically for this challenge, providing a highly reliable barrier against temperature excursions that could compromise medication integrity.

These two-part systems consist of an expanded polyurethane interior—known for its superior thermal resistance compared to EPS (expanded polystyrene)—housed inside a durable corrugated outer shell. This combination ensures GLP-1 medications stay within their safe temperature range, even during delays, fluctuating conditions, or high-impact handling. Whether shipped frozen, refrigerated, or ambient, these coolers provide the consistency needed to maintain efficacy throughout transit.

Why polyurethane coolers are ideal for GLP-1 shipments:

- Superior thermal resistance for extended cold chain protection

Polyurethane insulation maintains internal payload temperatures for significantly longer durations than EPS, ensuring compliance for GLP-1 medications even during extended delivery windows or supply chain disruptions. - Physical robustness against vibration, drops, and environmental stressors

The dual-layer design provides shock absorption and structural protection during shipping, helping prevent physical damage to vials, pens, or temperature sensors. - Available in standard and custom sizes to suit pharmacy fulfillment workflows of all scales

From centralized mail-order operations to local pharmacies expanding their delivery radius, these coolers can be tailored to meet precise volume, packaging, and logistics requirements—without added complexity.

Paired with Nordic® Ice-Eco Paper Gel Packs, these coolers create a highly efficient thermal barrier that supports GLP-1 stability from origin to destination. This layered system allows pharmacies and distributors to confidently scale delivery services without compromising quality or compliance. As demand continues to grow, selecting insulated shippers with proven performance will be essential for safeguarding patient outcomes and meeting evolving cold chain standards.

Temperature Monitoring: Visibility from Start to Finish

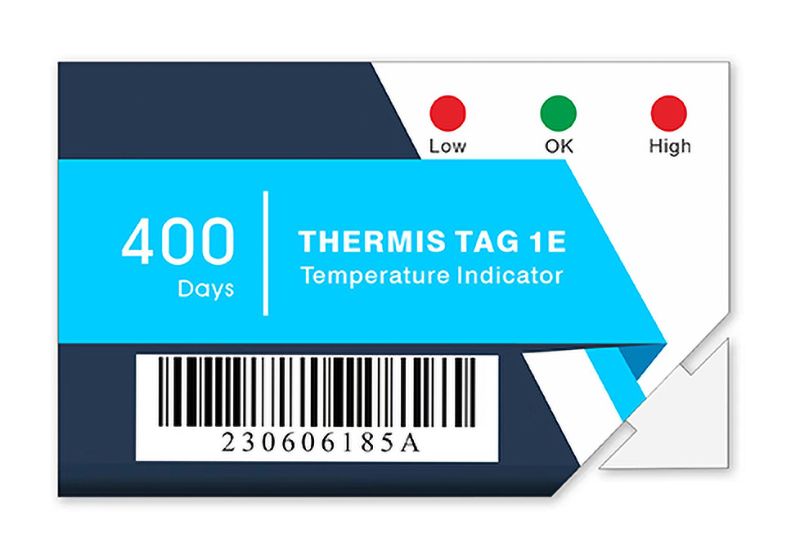

Even the best thermal packaging can’t guarantee success without real-time temperature data. To maintain full compliance with industry regulations and ensure consistent product integrity, pharmacies and distributors rely on compact, powerful sensors like the Thermis Tag 1E. These tools act as both an early warning system and a verification mechanism for GLP-1 cold chain performance.

This single-use LED temperature indicator adheres directly to shipping cartons and monitors internal package temperatures for up to 400 days. Its compact design, visual feedback, and long battery life make it ideal for both high-volume mail-order shipments and local pharmacy deliveries. Designed with a default alarm range of 2–8°C, the Thermis Tag is perfectly suited for GLP-1 medications, which are typically stored and transported within that narrow window to maintain efficacy.

This single-use LED temperature indicator adheres directly to shipping cartons and monitors internal package temperatures for up to 400 days. Its compact design, visual feedback, and long battery life make it ideal for both high-volume mail-order shipments and local pharmacy deliveries. Designed with a default alarm range of 2–8°C, the Thermis Tag is perfectly suited for GLP-1 medications, which are typically stored and transported within that narrow window to maintain efficacy.

Features that matter in GLP-1 cold chain monitoring:

- Visual LED alerts for temperature excursions

Provides a clear, immediate signal if the shipment has exceeded safe temperature limits, allowing for faster quarantine or investigation procedures. - Accurate tracking from -30°C to +70°C with ±0.5°C precision

Enables precise monitoring across a broad range of potential shipping conditions, ensuring medications stay within validated thermal thresholds. - Customizable start delays and alarm settings to match route requirements

Allows pharmacies to fine-tune sensor activation and sensitivity, optimizing for specific shipment profiles, transit durations, or regulatory standards. - IP68 protection to withstand the rigors of the pharmaceutical supply chain

Fully sealed against dust and water ingress, ensuring reliable operation in insulated shippers, refrigerated vehicles, or high-humidity environments.

More than a monitoring tool, temperature sensors enable proactive intervention, generate audit-ready data, and ultimately support patient confidence in the safety of their prescriptions. The Thermis Tag 1E adds an essential layer of traceability and compliance, helping pharmacies meet accreditation requirements and avoid costly product losses. As expectations for transparency and delivery assurance continue to rise, integrated temperature monitoring will remain a cornerstone of cold chain best practices for GLP-1 medications.

Integration for Cold Chain Confidence

Nordic Cold Chain Solutions offers more than individual components—it delivers a fully integrated cold chain system tailored to the unique demands of GLP-1 medication distribution. By aligning packaging technologies with pharmacy workflows, Nordic helps ensure that every shipment is protected from thermal deviation, mechanical damage, and regulatory noncompliance.

Each system is built around purpose-designed elements: gel packs that maintain product-specific temperature profiles, insulated containers that shield against environmental extremes, and temperature indicators that provide real-time visibility and traceability. Together, these tools form a cohesive defense against the risks that threaten cold chain integrity from fulfillment through final delivery.

Beyond the hardware, Nordic provides support that extends into training, implementation, and compliance guidance. This end-to-end approach not only helps pharmacies and distributors maintain product stability—it also supports operational efficiency and reinforces a commitment to patient safety across every touchpoint of the supply chain.

Elevating the Standard for GLP-1 Cold Chain Logistics

As demand for GLP-1 therapies grows, so do expectations around delivery integrity, sustainability, and regulatory compliance. Pharmacies and distributors can no longer afford to rely on legacy packaging or one-size-fits-all approaches. The risk is too great—and the opportunity for improvement too significant. Today’s cold chain strategies must balance performance, traceability, and environmental responsibility without adding complexity to fulfillment workflows.