From large-scale pharmaceutical distribution to frozen food freight, bulk cold chain logistics demand an uncompromising standard of thermal protection. Polyurethane (PUR) pallet shippers have emerged as the gold standard for transporting frozen goods over extended durations, combining superior insulation with structural durability and engineered precision. In environments where even minor temperature excursions can result in spoilage, efficacy loss, or regulatory noncompliance, PUR pallet shipping systems provide a proven, scalable, and high-performance solution.

This advanced packaging approach is transforming expectations in both life sciences and food-grade logistics, delivering reliable outcomes in demanding real-world shipping conditions. In pharmaceutical distribution, PUR pallet shippers support cold chain compliance, product stability, and regulatory readiness. In frozen food transport, they preserve quality and safety across complex routes, maintaining sub-zero conditions through heat exposure, transit delays, and handling variability.

The Science Behind PUR: Thermal Stability That Outperforms

Polyurethane’s intrinsic insulation properties distinguish it from traditional cold chain materials such as expanded polystyrene (EPS). With a lower thermal conductivity and higher resistance to temperature transfer, PUR enables the design of shipping systems that maintain frozen conditions for significantly longer periods. In transit environments subject to fluctuating ambient temperatures, PUR pallet shippers maintain internal payload temperatures with far greater resilience, even during prolonged idle times or cross-docking events.

PUR’s dense cellular structure reduces thermal bridging and enhances insulation consistency across surfaces, minimizing hot spots and ensuring temperature uniformity throughout the payload. This makes PUR the material of choice for biologics, vaccines, high-value specialty drugs, and temperature-critical frozen food products that must arrive intact and compliant after 24, 48, or even 72 hours in transit.

Multi-Component Engineering for Maximum Protection

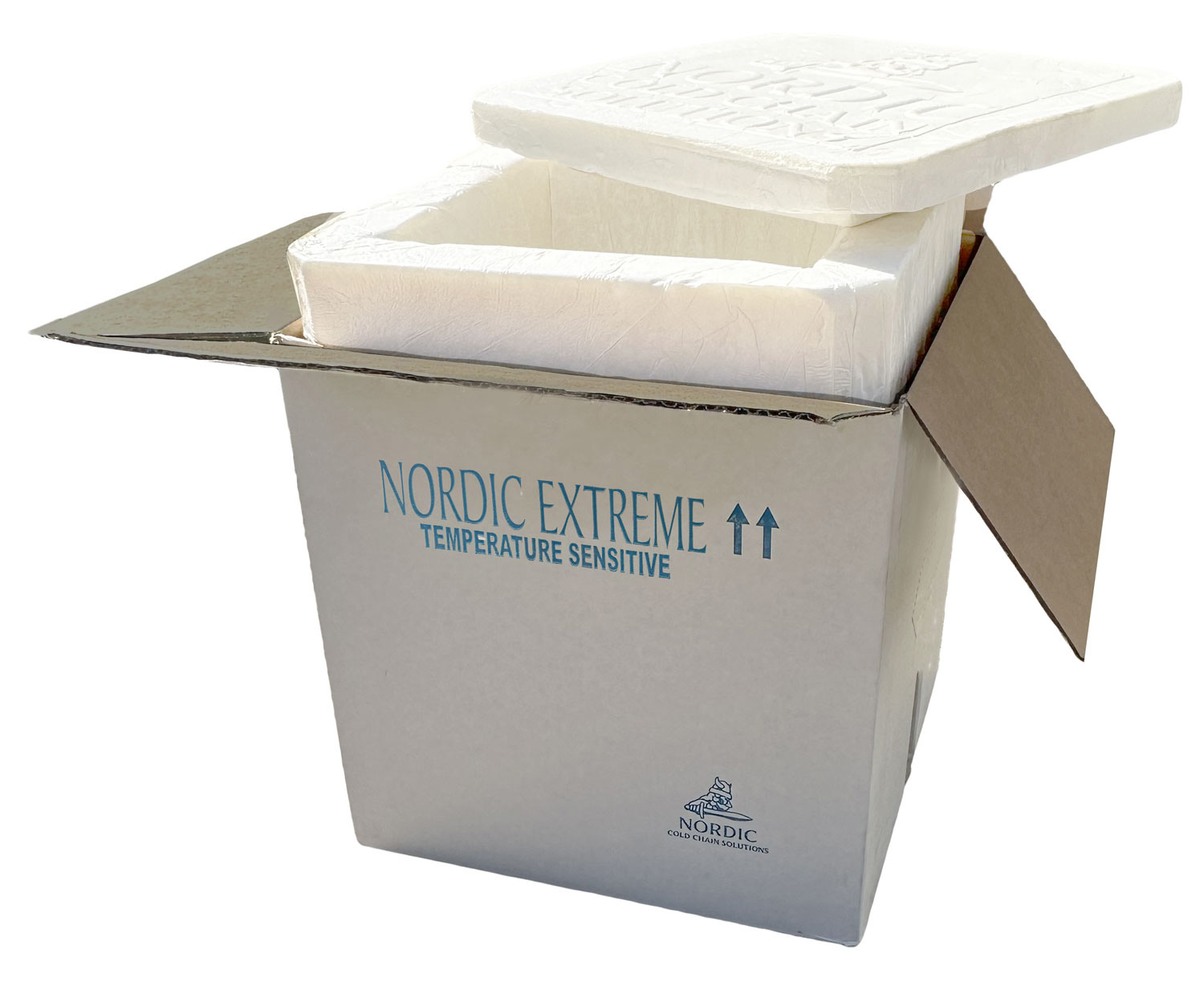

Nordic Cold Chain Solutions’ PUR pallet shippers are engineered as a dual-component system, integrating a high-density rigid polyurethane core with a structurally reinforced corrugated exterior. This composite architecture is optimized for thermal retention and mechanical durability, forming a cohesive barrier against conductive heat transfer and physical compromise during transit. The internal PUR enclosure establishes a controlled thermal environment, characterized by low thermal conductivity and minimal temperature variance across the payload chamber.

Inner PUR Casing:

Encapsulates the frozen payload in a controlled microenvironment engineered for thermal consistency.

Corrugated Outer Shell:

Shields against mechanical stress, punctures, and environmental hazards during warehousing and freight handling.

This two-tiered configuration delivers a high-performance cold chain solution capable of withstanding the rigors of real-world distribution. Even under repeated handling cycles, variable ambient exposures, and prolonged dwell times, Nordic’s PUR pallet systems preserve thermal integrity and payload stability without degradation.

Performance Verified Under Industry Standards

All Nordic Extreme PUR Frozen Shippers undergo rigorous laboratory testing in accordance with ISTA 7E protocols, which simulate real-world variables such as ambient temperature fluctuations, orientation shifts, and transit delays. These controlled assessments are designed to verify both thermal hold duration and structural integrity under stress conditions representative of global distribution environments. Testing also includes stress-point analysis to evaluate insulation performance under peak thermal loads and ensure payload stability throughout the transit cycle.

All Nordic Extreme PUR Frozen Shippers undergo rigorous laboratory testing in accordance with ISTA 7E protocols, which simulate real-world variables such as ambient temperature fluctuations, orientation shifts, and transit delays. These controlled assessments are designed to verify both thermal hold duration and structural integrity under stress conditions representative of global distribution environments. Testing also includes stress-point analysis to evaluate insulation performance under peak thermal loads and ensure payload stability throughout the transit cycle.

Through this process, Nordic’s PUR shippers consistently meet or exceed industry benchmarks for frozen transit durations of one to three days. Their performance is not based on theoretical models but on repeatable, data-backed results that demonstrate reliable thermal protection across critical shipping scenarios. Each shipper is supported by a full qualification package, enabling pharmaceutical and food clients to meet regulatory documentation requirements with confidence.

Ideal for Long-Duration Pharmaceutical and Biologic Freight

The stakes in pharmaceutical logistics are measured not only in financial terms but also in patient outcomes. Biologics, vaccines, and specialty injectables often require stringent temperature control across the entire supply chain, with tolerance for deviation measured in fractions of a degree. PUR pallet shippers align precisely with the technical, operational, and regulatory demands of these high-risk, high-value therapies.

As biologics continue to grow in market share and regulatory scrutiny intensifies under guidelines such as Good Distribution Practices (GDP) and USP <1079>, PUR packaging offers a suite of measurable advantages:

- Prolonged thermal hold for international and multi-leg shipping

Maintains stable sub-zero temperatures for extended transit windows, including multi-day routes with stopovers, customs inspections, and unforeseen delays. - Optimized configurations for high-volume pharmaceutical freight

Accommodates bulk shipments of vials, prefilled syringes, or cartons without compromising airflow or temperature uniformity, ensuring consistent protection at scale. - Compliance-ready documentation from lab-tested performance data

Supports audit preparedness with thermal profiles, ISTA 7E qualification, and detailed performance records for regulatory submission. - Structural durability to protect fragile vials, syringes, or boxed packaging

Withstands vibrations, stacking pressures, and impact events common in air, ground, and intermodal freight environments while maintaining package integrity. - Compatibility with gel packs, dry ice, or other refrigerant systems

Flexible enough to integrate with a range of cooling strategies, enabling precise thermal tuning based on payload sensitivity and route complexity.

The capacity of PUR shippers to deliver extended-duration thermal protection reduces the risk of temperature excursions during customs delays, warehouse transfers, or last-mile delivery handoffs. Their performance not only safeguards product efficacy but also strengthens supply chain resilience, giving pharmaceutical manufacturers and distributors greater control over logistics continuity and regulatory risk mitigation.

Frozen Food Distribution at Scale

While pharmaceutical applications often take center stage, the frozen food industry is equally reliant on uncompromising cold chain performance. Regulatory demands, brand reputation, and public health concerns converge in the transportation of frozen goods, where even minor thermal deviations can lead to quality loss, spoilage, or microbial risk. PUR pallet shippers enable large-scale distribution of perishable products without compromising safety, taste, or shelf life, which remains critical for both manufacturers and retailers.

PUR systems are especially valuable for frozen meats, seafood, dairy products, and ready-to-eat meals that require deep-frozen stability over extended transit durations. These goods often pass through variable climates and multimodal routes into decentralized distribution networks. Nordic’s high-performance PUR shippers are built to navigate these complexities while maintaining product integrity from origin to destination. Specifically, they provide:

Consistent temperature from dock to door

Maintains strict thermal thresholds throughout all phases of distribution, from initial loading to final delivery, even in ambient environments exceeding 100°F.

Protection from condensation and freezer burn

Insulated enclosures prevent moisture intrusion and rapid temperature fluctuations, reducing surface crystallization and textural degradation in proteins and produce.

Extended usability during warehouse staging or route delay

Retains sub-zero conditions during prolonged storage at transfer points or unexpected route disruptions, minimizing spoilage risk when schedules change.

Versatility across truckload, air, and intermodal freight

Built to perform consistently across diverse logistical frameworks, including last-mile carriers, cold storage hubs, and long-haul refrigerated transport.

Incorporating real-time temperature monitoring devices and leveraging optimized refrigerant configurations, Nordic’s PUR systems deliver a closed-loop thermal solution from production to point of sale. By minimizing internal air volume and maximizing insulation performance, these shippers enhance not just transport efficiency but also product safety, brand protection, and regulatory compliance, which are all critical pillars in an increasingly scrutinized global food supply chain.

Engineered for Real-World Logistics and Scalable Demands

Cold chain logistics operate within inherently variable and unpredictable conditions. Unplanned delays, shifting ambient temperatures, and cross-carrier transfers all introduce risks to payload stability. PUR pallet shippers from Nordic Cold Chain Solutions are engineered to meet these challenges head-on, delivering consistent thermal performance even under fluctuating conditions. Each system is designed around key variables such as transit duration, climate exposure, regulatory requirements, and payload configuration to ensure reliable protection in diverse shipping environments.

Cold chain logistics operate within inherently variable and unpredictable conditions. Unplanned delays, shifting ambient temperatures, and cross-carrier transfers all introduce risks to payload stability. PUR pallet shippers from Nordic Cold Chain Solutions are engineered to meet these challenges head-on, delivering consistent thermal performance even under fluctuating conditions. Each system is designed around key variables such as transit duration, climate exposure, regulatory requirements, and payload configuration to ensure reliable protection in diverse shipping environments.

Beyond technical resilience, Nordic’s PUR solutions offer scalability to match evolving operational needs. Whether supporting biotech firms distributing clinical trial doses or food producers scaling national distribution, these shippers are available in standard and custom configurations to suit varying volumes and use cases. This adaptability ensures that whether you’re shipping 100 units or 100,000, each load is supported by precise thermal engineering, optimized kitting, and logistics expertise built for real-world performance.

Quality That Starts at the Source

Behind every Nordic PUR pallet shipper is a commitment to engineering excellence, quality assurance, and client-specific performance. Every component is backed by in-house cold chain testing and decades of industry insight. From preconditioning strategies to final shipment optimization, Nordic’s integrated approach delivers total cold chain continuity.

Our experts collaborate with your operations, QA, and regulatory teams to ensure seamless implementation. We don’t just ship cold; we engineer certainty into every shipment.

Explore the Proven Power of PUR

Bulk frozen shipping doesn’t allow for error. Whether you’re protecting biologics with microthermal tolerances or safeguarding frozen food for nationwide distribution, PUR pallet shippers from Nordic Cold Chain Solutions deliver reliability without compromise.