The cold chain packaging industry is rapidly evolving, with new technologies and materials being developed to meet the demands of the market. Innovative advancements in cold chain packaging are revolutionizing the way food, pharmaceuticals, and other temperature-sensitive products are shipped and stored. With a focus on ensuring that products remain at the desired temperature throughout the entire shipping process, cold chain packaging is becoming an increasingly important part of the logistics industry. As the demand for temperature-controlled products continues to increase, so too does the need for reliable, cost-effective cold-chain packaging solutions. From improved insulation materials to advanced tracking systems, new technologies are allowing for more efficient and effective cold chain packaging solutions.

New Technologies for Cold Chain Packaging

Innovations in cold chain packaging are on the rise as companies look to keep products safe while minimizing waste and preserving product viability. Cold chain packaging is a critical aspect of many industries, including healthcare, agriculture, and the food service industry. Companies understand that proper temperature control during shipping and storage helps preserve product integrity for consumers, and minimize costs associated with spoilage or contamination while reducing their carbon footprint.

Today’s advancements in cold chain packaging technologies are designed to ensure optimal temperature ranges within specified timeframes through a variety of innovative solutions. These include:

Today’s advancements in cold chain packaging technologies are designed to ensure optimal temperature ranges within specified timeframes through a variety of innovative solutions. These include:

- Insulated Containers – The construction material may be plastic foam (foam-in-place systems), molded expanded polystyrene (EPS), vacuum insulated panels (VIPs), waffle walls, or injection molded parts – whatever best meets packing insulation needs based on the perishability of the cargo being shipped. Because each has its pros and cons when it comes to temperature retention levels, durability, and cost considerations must be taken into account when determining which type of container will be used.

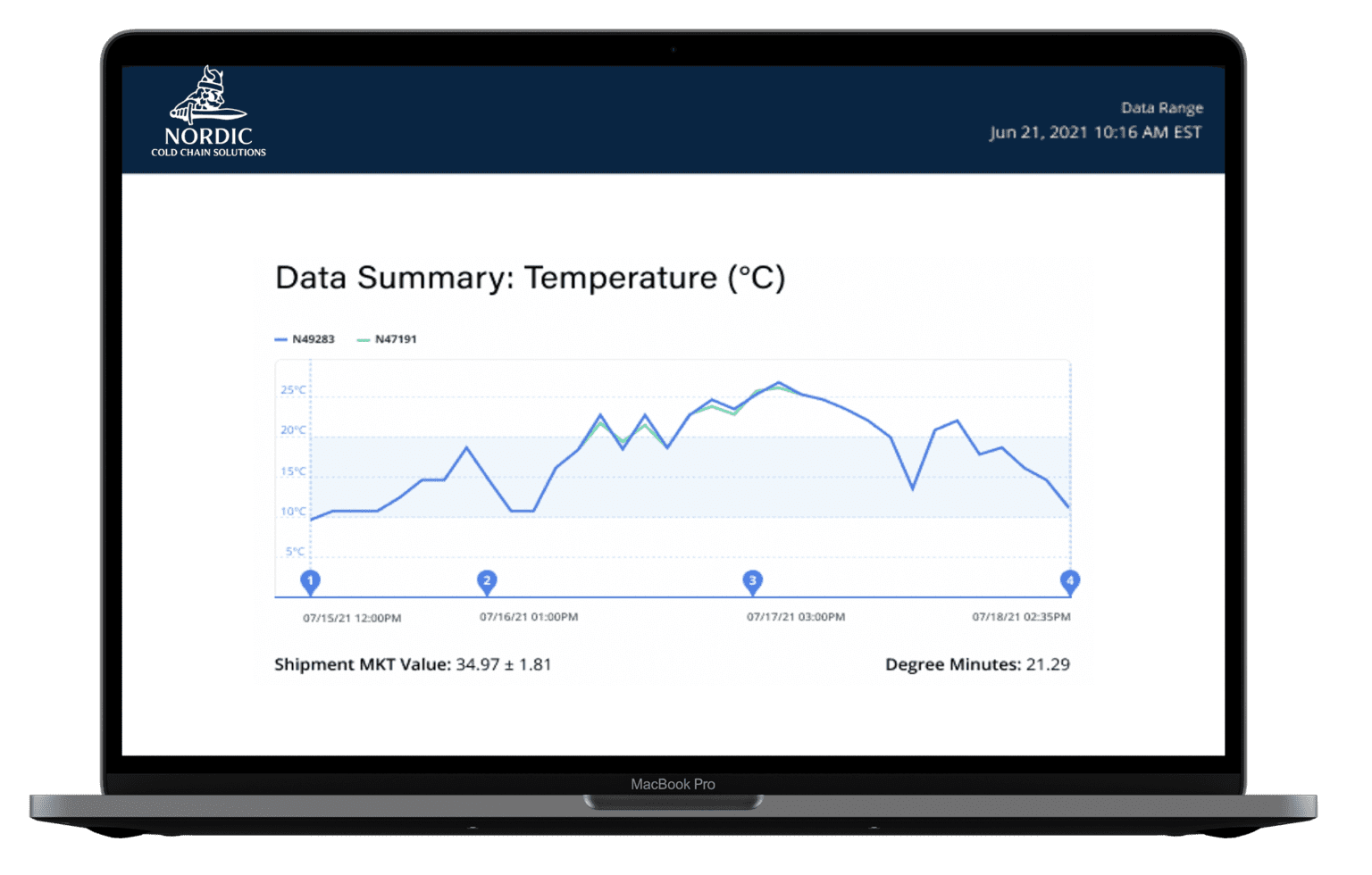

- Temperature Management Systems – These can range from built-in devices inside containers that sense changes in ambient temperatures along with measuring data points such as cumulative heat summation or Delta T values as well as integrated software systems that track real-time ambient readings via cloud technology connected to cellular networks or satellites depending on application need. These allow shippers not only to monitor internal environment conditions but also provide external visibility for stakeholders throughout the supply chains who need access to readouts concerning shipment contents status along its route.

- Active Packaging Solutions – This includes components such as phase change materials (PCMs), desiccants, or combination versions where PCM & desiccant particles are infused inside multiple foil layers trapping both together within sealed pouches placed inside packages meant for outdoor environments needing superior level protection against moisture build-up.

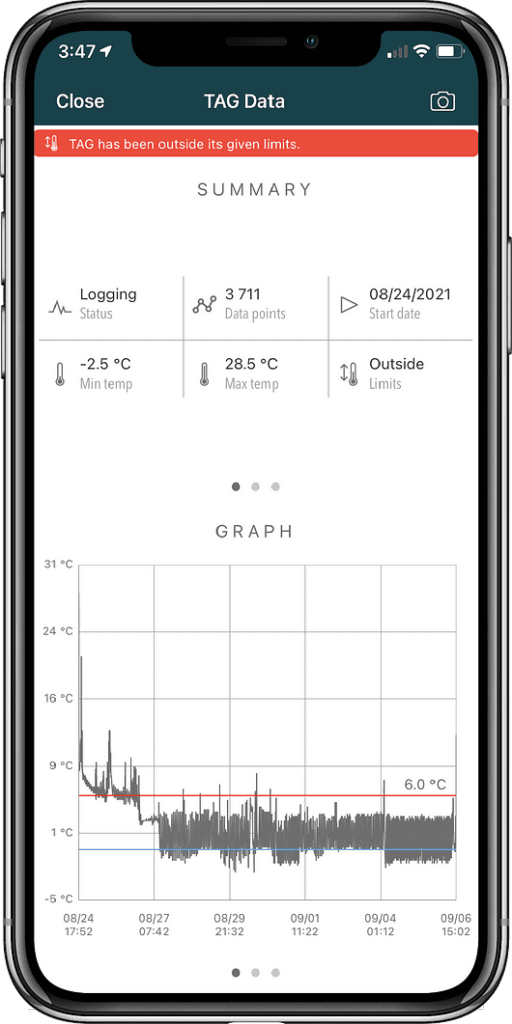

- Intelligent Labels – These special tags can comprise electronic components embedded between paper layers that record variable measurements related to environmental exposure factors like pressure light vibration etc., allowing further insight into package behavior during shipment/ transport stages especially those subject to more severe challenges due to being exposed elements.

- Smart Monitoring Tools– Advancements made here encompass real-time data gathering capabilities enabling shippers to gain info related to exact location details, temperature humidity readings, shock & tip over warnings plus GPS tracking features enabling users to know immediately if any potential problems arise outside pre-defined parameters should an interruption occur during transit.

Market Outlook for Cold Chain Packaging

The global cold chain packaging market is set to experience rapid growth over the next decade. According to a recent analysis conducted by Grand View Research, the market size was valued at USD 22.64 billion in 2021 and is anticipated to reach USD 115.08 billion by 2030 with a CAGR of 19.8% from 2023 to 2030. This projected growth can be attributed to several factors including increasing demand for temperature-controlled food product transportation, stringent food safety regulations, large investments in research & development activities related to cold chain technology, and rising use of automation tools for storage & transport systems designed specifically for perishable goods.

To meet these consumer demands, various advancements have been made over the past few years in terms of materials used for packaging such as insulated boxes and containers made from expanded polystyrene (EPS) foam and corrugated cardboard amongst others which helps retain heat/cold keeping products fresh longer even during long-distance travel between countries or regions with different climates. Additionally, technologies like RFID tagging are being increasingly used as tracking devices on both the inner and outer packaging that enable companies or shippers to monitor temperatures accurately during transit times so that they know if any changes occur along with their location–making it easier for them to take proactive measures quickly should any issues arise while en route.

How Nordic is Getting Started

Innovations in cold chain packaging are becoming increasingly important for businesses that require their perishable or other temperature-sensitive products to be delivered safely and efficiently. Nordic Cold Chain Solutions is an industry leader in this area, offering quality and design-tested products to a wide variety of commercial and industrial markets.

Data Loggers: One of the most impressive innovations we offer is real-time data logging solutions. With these tools, customers can get detailed information on the exact temperatures along their supply route – allowing them to constantly monitor their shipments and respond quickly if something isn’t right. This helps ensure that products stay safe during transport, even during extreme hot or cold weather conditions.

Nordic Drain Safe®: Another notable product offered by Nordic Cold Chain Solutions is called Nordic Drain Safe® Gel Refrigerant Packs. These packs are made from durable poly gels that provide reliable performance over longer periods than traditional gel packs. We also have the added benefit of being 100% safe for disposal into household drains, meaning that businesses can make sure they’re not contributing any waste to landfills.

Experience the Advanced Cold Chain Solution With Nordic

Advances in cold chain packaging have made a significant impact on the food and pharmaceutical industries. Whether it’s improved speed of shipping, reduced wastage, increased safety, and security, or better temperature control – there is definite room for improvement from manufacturers. Now that industry players have seen the light, it is expected that further advancements will be made in the near future. Awareness and initiatives such as Nordic cold chain solutions drive innovation and investments into research and development of new processes and technologies to ensure optimal end-to-end delivery solutions.

Looking for the most reliable cold chain packaging solution? Contact us today!