Cold chain packaging for pharmaceuticals is no longer judged solely by whether products arrive intact. In today’s regulatory and operational landscape, the standard is validated performance: proof that packaging can withstand real-world stressors and still maintain uncompromising protection for life-changing therapies. For GLP-1 medications such as semaglutide and tirzepatide, this level of assurance is not optional. It is essential for preserving drug efficacy, patient safety, and the reputation of every distributor and pharmacy involved in the supply chain.

The Nordic GLP-1 Express Pack™ was developed with this reality in mind. More than an insulated mailer, it is a design-tested system that integrates refrigerants, insulation, and monitoring into one streamlined kit. Each component has been engineered to address the vulnerabilities of GLP-1 logistics, from last-mile delivery risks to long-duration summer heat lanes. Together, they form a validated solution that specialty pharmacies and healthcare distributors can depend on with confidence.

Why GLP-1 Shipments Demand More Than Generic Packaging

GLP-1 therapies have quickly become some of the most prescribed medications in the world, driving unprecedented shipping volumes through both specialty pharmacies and direct-to-patient channels. This surge places enormous pressure on cold chain systems that were never designed for such scale.

Traditional insulated mailers or foam coolers may provide short-term thermal protection, but they were not engineered for the specific challenges of GLP-1 products:

- Strict temperature requirements between 2°C and 8°C, with little tolerance for deviation.

- High prescription volumes creating bottlenecks and variable handling conditions.

- Decentralized delivery models that rely heavily on couriers, postal carriers, and last-mile networks.

- Increased regulatory scrutiny, particularly under URAC-compliant practices, which require pharmacies to demonstrate robust safeguards.

In this environment, packaging must do more than keep products cold. It must be validated against real-world stressors, generate confidence through monitoring, and eliminate guesswork from packouts.

The Express Pack™: Three Components, One Integrated Solution

The strength of the Nordic GLP-1 Express Pack™ lies in its simplicity. By combining three purpose-built components into one kit, Nordic removes the variability that often undermines cold chain reliability. Each element plays a distinct role in protecting GLP-1 shipments, yet the system functions cohesively to deliver unmatched performance.

1. Nordic Ice® Bricks: Consistent Refrigerant Performance

Refrigerants are the backbone of any cold chain shipment, yet not all are created equal. Gel packs often deform or leak during transit, compromising packout stability. The Nordic Ice® Brick solves this problem with a semi-rigid structure that maintains its shape through freezing, thawing, and transport.

Refrigerants are the backbone of any cold chain shipment, yet not all are created equal. Gel packs often deform or leak during transit, compromising packout stability. The Nordic Ice® Brick solves this problem with a semi-rigid structure that maintains its shape through freezing, thawing, and transport.

Each brick is filled with a precisely measured coolant and vacuum-sealed for consistency. This ensures predictable performance across shipments, reducing the variability that can trigger temperature excursions. For GLP-1 therapies, which must remain stable across transit windows ranging from 24 to 72 hours, this reliability is essential.

The benefits extend beyond thermal performance:

- Tight packout tolerances reduce void space and minimize thermal fluctuation.

- Durable design resists leaks and maintains product positioning throughout distribution.

- Space efficiency lowers shipping costs by allowing for more compact packaging formats.

By starting with refrigerants that are engineered for predictability, the Express Pack™ lays the foundation for compliance-driven performance.

2. Insulated Expansion Mailers: Lightweight Protection With Validated Durability

Insulation is the second pillar of thermal control, and here the Express Pack™ leverages cotton-based insulated expansion mailers. These slim-profile mailers reduce heat transfer while providing a lightweight, recyclable alternative to rigid foam coolers.

Insulation is the second pillar of thermal control, and here the Express Pack™ leverages cotton-based insulated expansion mailers. These slim-profile mailers reduce heat transfer while providing a lightweight, recyclable alternative to rigid foam coolers.

Unlike generic envelopes, these mailers are ISTA-certified, meaning they have been laboratory-tested to meet industry benchmarks for thermal insulation. They also offer proven duration performance, holding shipments below 15°C for up to 36 hours depending on configuration.

Key advantages include:

- Validated thermal stability across variable shipping lanes.

- Slim design that saves warehouse storage space and reduces dimensional weight charges.

- Biodegradable cotton insulation that aligns with sustainability goals.

- Durability in handling, with a corrugated-like structure that resists crushing.

For pharmacies scaling prescription fulfillment during seasonal surges, the compact format of expansion mailers is a logistical advantage. They store flat, pack quickly, and reduce waste compared to bulky foam containers—all without sacrificing compliance.

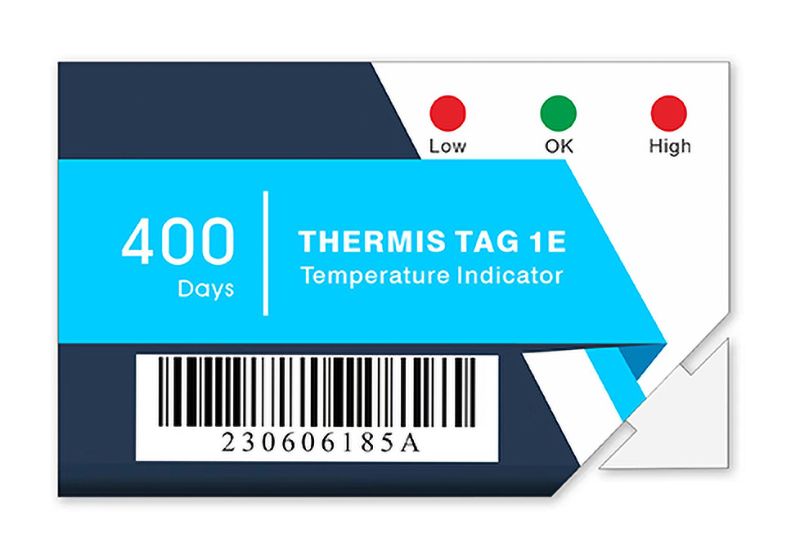

3. Thermis Tag 1E: Compliance Through Monitoring

The final component, the Thermis Tag 1E single-use LED temperature indicator, closes the compliance loop. While refrigerants and insulation preserve thermal conditions, regulators and pharmacies increasingly require proof that these conditions were maintained.

The Thermis Tag 1E provides this visibility through:

- LED indicator lights that visually confirm if temperature excursions occurred.

- ±0.5°C accuracy across a wide range (-30°C to +70°C).

- Configurable alarms for cumulative or single-event excursions.

- 400-day monitoring capacity, allowing for extended tracking if needed.

- IP68 protection against moisture and dust.

By attaching directly to the package, the device provides immediate, easy-to-read feedback at the point of delivery. For specialty pharmacies managing URAC standards, this capability translates directly into documented compliance and reduced liability.

Real-World Reliability With Built-In Efficiency

Lab validation provides a foundation, but the true measure of performance lies in how packaging withstands real-world stressors. The Nordic GLP-1 Express Pack™ has been tested against the realities of pharmaceutical logistics, from summer hot lanes exceeding 35°C to multi-day courier delays and variable handling across postal networks. In each case, it maintained payload stability within the critical 2°C to 8°C range, outperforming generic mailers that often fail under unpredictable conditions.

Yet validated performance is only part of the value. The Express Pack™ was also engineered for operational efficiency, enabling pharmacies and distributors to meet surging GLP-1 demand without added complexity. Pre-configured components accelerate packouts, slim-profile mailers reduce storage needs, and minimized dimensional weight lowers shipping costs. Standardized kits further simplify training, ensuring staff can achieve compliance quickly and consistently. This combination of real-world reliability and built-in efficiency makes the Express Pack™ a scalable solution for organizations facing both regulatory pressure and rapid growth.

Validated Protection, Patient-First Design, Proven Confidence

In GLP-1 cold chain logistics, even minor temperature excursions can compromise drug efficacy, put patient safety at risk, and damage pharmacy reputations. Rising prescription volumes and increasingly complex delivery networks only heighten these risks, making validated packaging an operational necessity rather than a competitive advantage. The Nordic GLP-1 Express Pack™ answers this need by doing more than protecting product, it safeguards patient trust, ensures regulatory compliance, and gives pharmacies the confidence to scale fulfillment without fear of product loss.

What sets Nordic apart is a design philosophy built specifically for GLP-1 therapies. Every component of the Express Pack™, from semi-rigid Nordic Ice® Bricks to ISTA-certified insulated expansion mailers and the Thermis Tag 1E temperature indicator, has been engineered and tested to perform under real-world stress. This patient-first approach reflects a simple truth: GLP-1 therapies are more than shipments; they are critical treatments that demand uncompromising care at every stage of the cold chain.

With validated performance and design-tested resilience, the Express Pack™ sets a new benchmark for GLP-1 cold chain packaging. By eliminating guesswork and providing proven protection from pharmacy to patient, it delivers confidence where the margin for error is razor-thin.